| DEX: (D002) fault_states — Faults related to products | Date: 2007/09/14 16:11:29 Revision: 1.28 |

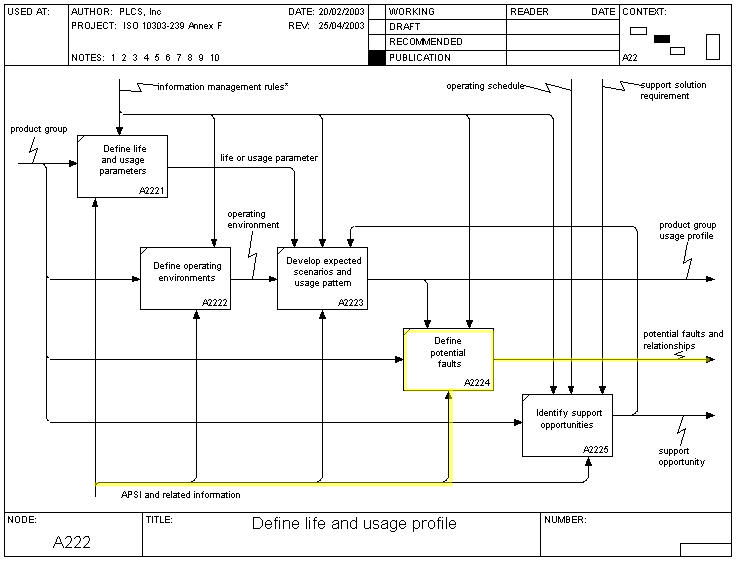

The ISO 10303-239 PLCS Application Activity Model (AAM) is an IDEF0 representation of the business activities that set the scope and information requirements for the PLCS standard. The model is composed of a set of figures and a set of definitions of these business activities and their associated information flows.

IDEFØ provides a graphical notation for function modeling of an organization or system. Activities can be described by their inputs, outputs, controls and mechanisms (ICOMs).

This DEX supports a subset of these business activities and information flows. These are highlighted in yellow in the figure Figure 1.

The information flows marked with an asterisk are not explicitly represented within PLCS. This information is instead transferred by other means, e.g., handled by a document.

The activity labels in the AAM views above have the following definitions:

action to determine the potential faults or other degraded states that the support solution shall address, including cause, effect and other relationships between them, as applicable to each product function requiring support, part, and attachment slot

NOTE The ARM of this part of ISO 10303 defines the concept of predicted states of a product and this concept is appropriate for representation of faults. A product can be either a part of a function. The sequences of individual faults involved in a failure can be represented by the relationship between predicted states.

The ICOM arrow labels in the AAM views above have the following definitions:

set of assured and related information used to develop and deliver support for a product in focus, including feedback from using and supporting the product over its life cycle

NOTE Related information includes records of the history of the usage or support of realized products, design and support analysis results and reasons why decisions were taken. Such information includes design and failure analysis records, logistic support analyses, running hours, environment descriptions, operating profiles; test results, records of maintenance activities, resources used, and faults found plus any other content deemed relevant to life cycle support.

identification and description of each potential fault or other degraded state that can affect each part, function or usage occurrence in each operating environment, including cause, effect or other relationships between relevant states

NOTE The product functions can be represented by a functional breakdown. Faults can be defined as product states.

© OASIS 2010 — All rights reserved