| DEX: (D002) fault_states — Faults related to products |

Date: 2007/09/14 16:11:29

Revision: 1.28

|

Information Overview

General administrative information includes all the information to uniquely identify and describe

the result from a specific formal fault state analysis.

This would be comparable to the header information in a FMECA worksheet.

This includes:

- Identification of an individual revision of the fault state analysis result;

- Status such as draft, issued etc;

- Identification of the top item product to which the fault state analysis result relates;

- Author;

- Applicable operational context(s);

- Dates;

- Approval(s).

![[warning:]](../../../../images/dex/warning.gif) Error I1; The image filename: ../fault_state_worksheet.PNG suffix (PNG)is uppercase

Error I1; The image filename: ../fault_state_worksheet.PNG suffix (PNG)is uppercase

Figure 1 — Example of a presentation of a fault state analysis result

Each record in the detail section of a fault state analysis result identifies the element

in a product breakdown (system, functional, assembly etc) to which a failure mode applies.

Each breakdown element considered in the DEX may have one or more assigned failures modes.

The following information should be provided for each failure mode identified:

- Failure mode description and characterization;

- Consequences (Failure effects);

- Criticality assessment.

Failure mode description and characterization

Each failure mode is characterized by:

- Identification;

- Description;

- Classification;

- Predictability;

- Detection method;

- Contexts such as operational state, mission phase etc.

Typical failure mode classes are (based on Moubray - 'Reliability centered maintenance'):

- Deterioration

- Fatigue

- Corrosion

- Abrasion

- Erosion

- Evaporation

- Degradation of insulation

- Lubrication failure

- Lack of lubrication

- Failure of lubrication

- External effect

- Contamination

- Dirt

- Accident

- Sabotage

- Adverse environmental conditions

- Disassembly

- Failure of welds, soldered joints or rivets due to fatigue

- Failure of threaded components such as bolts, electrical connections or pipefittings

- Loosening of threaded components such as bolts, electrical connections or pipefittings

- Failure of locking mechanisms such as split pins, locking wire etc

- Human error

- Increase in desired performance

Failure mode predictability may be represented by:

- Qualifiers

- Highly predictable

- Unpredictable

- Value of P-F Interval (interval between the point when a potential failure becomes detectable and

the point at which it degrades into a functional failure)

- Value of ß parameter of Weibull distribution

NOTE

Failure mode predictability describes the relationship between the product design's failure

characteristics and an individual product's failure characteristics. For example the product design

mean time to failure by wear out is 5000 hours. If every individual product failed between 4900

and 5100 hours this would be described as a highly predictable failure mode; if however every

individual product failed in the range 1000 to 9000 hours this would be described as an unpredictable

failure mode.

Typical detection methods are:

- Alarm

- Built in test

- Non-destructive examination

- Vibration analysis

- Particle analysis

- Chemical analysis

- Spectrographic analysis

- Visual

- Audible

- Olfactory

The identification of the context in which a failure mode is predicted to occur, may be defined as one or more of

the following:

- Operating state

- Environment

- Mission phase

- Start up

- Take off

- Cruise

- Landing

- Shut down

Consequences

Consequences may be characterized by:

- Description

- Classification

- Reference to the affected function, system etc

Typical classes of relationships between the failure mode and its consequences are:

- Cause effect

- Primary / Secondary

- Failure effect

- Local effect

- Next higher effect

- End effect

- Boolean

Criticality indicator

Criticality indicator is based on the combination of the severity of faults and

the likelihood of a cause, fault or consequence occurring

Typical classifications of severity are:

- Safety [source: def stan 02-45]

- Death

- Serious injury

- Injury

- Treatment

- Environmental [source: Rolls-Royce]

- Contamination of land

- Ground-water pollution

- Depletion of non-renewable resources

- Noise nuisance

- Operational [source: def stan 02-45]

- Loss of platform

- Loss of mission

- Availability less than specified

- Minimal risk to mission or platform

- Non-operational [source: def stan 02-45]

- Economic [source: def stan 02-45]

- Catastrophic

- Critical

- Marginal

- Negligible

- Hidden / evident [source: def stan 02-45]

Typical representations of likelihood are:

- Probability

- Frequency

-

EXAMPLE

< 10.000 hrs, > 200 landings, < 4 years

- Qualitative [source: def stan 02-45]

- Frequent

- Probable

- Occasional

- Remote

- Improbable.

NOTE

Criticality code can be derived from the combination of severity and likelihood.

Note

Notes can be made for any failure mode record. Examples of notes are additional information

on product changes or tasks required to manage the effects of the failure mode under

consideration.

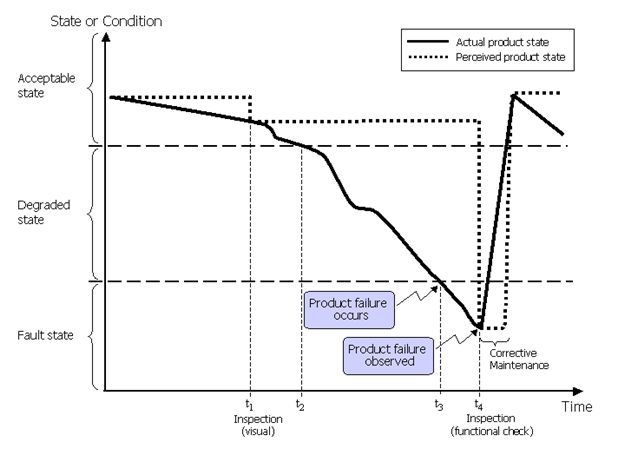

Each element in a product breakdown may have a range of values defining its

degraded or fault state, i.e. state definitions with related properties.

Examples of values that can be used to determine the respective state are:

- Temperature

- Speed

- Pressure.

Figure 2 — State of a product over time

©

OASIS

2010 — All rights reserved