| Business DEX (LOGSA002):— support_equipment_recommendation_data | Date: 2010/12/29 19:36:19 Revision: 1.20 |

The Support Equipment Recommendations Data Exchange Set provides the specification for the transfer of support equipment recommendation data and calibration requirements.

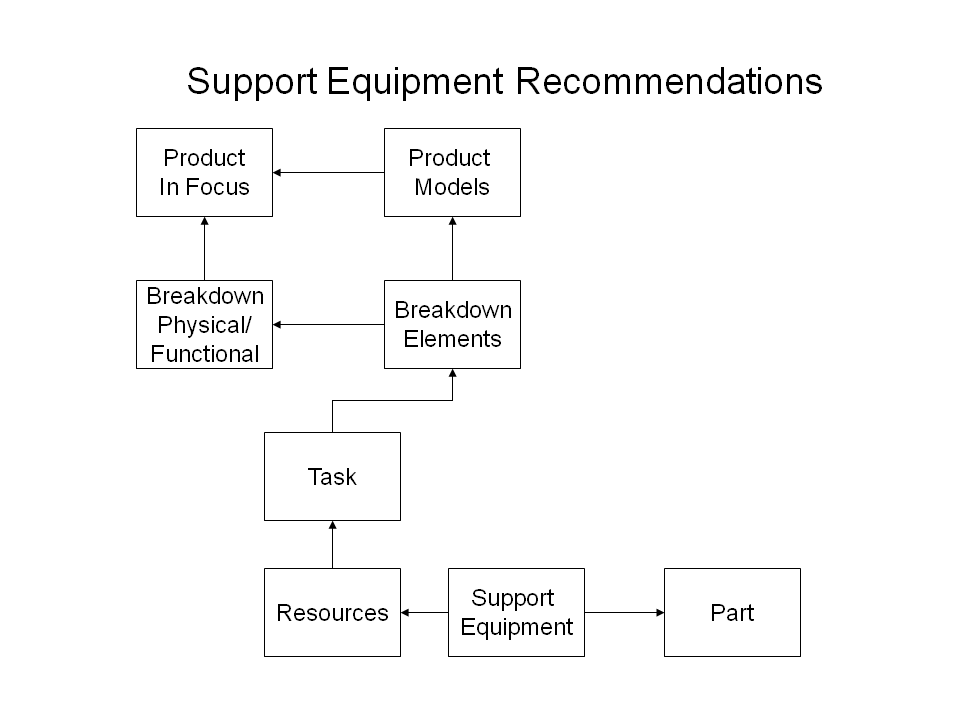

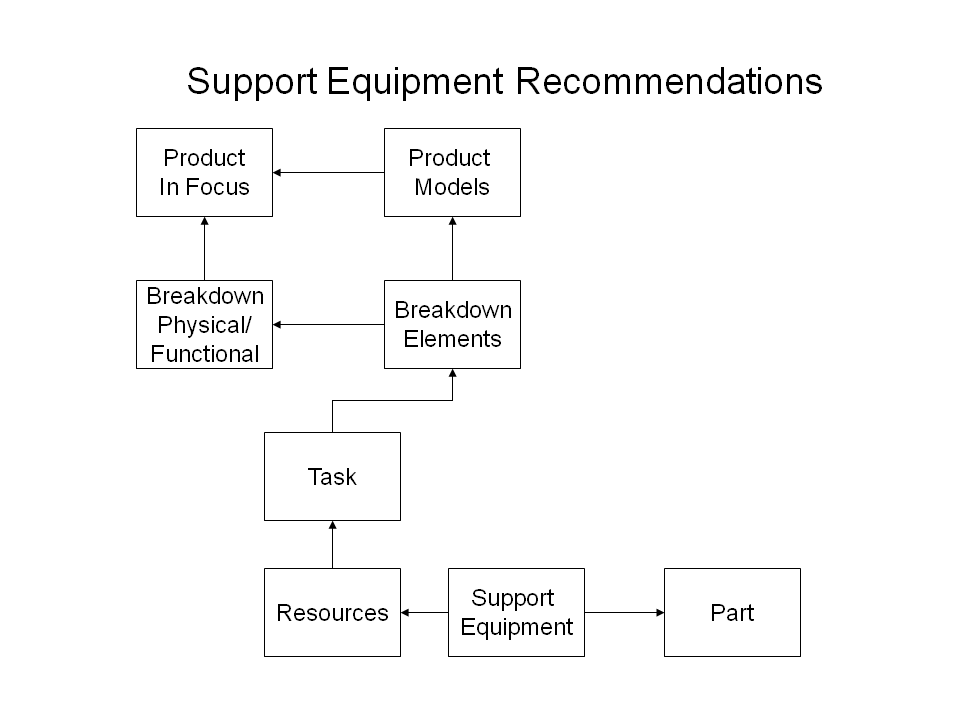

Support Equipment Recommendations Data specification information is summarized in Figure 2 below.

The product in scope and its component assemblies and parts. Can be either a part, or an element in a logical breakdown structure of a defined end item. This is normally defined by an End Item Acronym Code.

The product in focus can have different versions of the product, each of which, has a different breakdown. Models are normally identified by a Usable on Code.

The product in focus and its product model breakdowns can be represented via a physical breakdown (e.g. follows the design drawing structure) or a functional breakdown (e.g. represents functions of the product, propulsion, fuel, communications, etc). Breakdowns may also be hybrid or zonal.

The identifier assigned to each physical or functional element in the breakdown of the product. An Logistics Support Analysis Control Number is normally used for the breakdown element.

A maintenance task is a defined maintenance procedure that is to be performed on a defined product.

A task may require a set of resources in order to execute the task. For this data exchange set the specific resources are limited to support equipment.

Captures the detailed characteristics of support equipment that are required to perform specific tasks. Support equipment can be associated with specific breakdown elements (i.e. units under test) which would include identification of interconnecting devices, test program sets and operational test programs.

The realization of a breakdown element normally derived from the engineering design or the product data model.

© OASIS 2010 — All rights reserved