| Business DEX (LOGSA004):— operations_and_maintenance |

Date: 2010/12/29 16:18:09

Revision: 1.14

|

For the purposes of this specification, the following terms apply:

additional_requirements

A narrative description of any specifications or requirements (related to the anticipated operation of the system, or the

environment in which the system will be operated and maintained) that cannot be documented under the detailed specification/requirements

data.

alternate_logistics_support_analysis_control_number_code (ALC)

A code used to allow documentation of multiple models of a system/equipment, or alternate design considerations of an item,

using the same LCN breakdown.

NOTE:

- ALC of zero, zero 00 will always be used as the basic system. There are no blanks allowed. ALCs will be assigned from 01

to ZZ in ascending order.

- ALC equates to S1000D Disassembly Code Variant, which is a constituent element of the Data Module Code.

annual_number_of_missions

The estimated or specified mean number of missions an item will be expected to accomplish in one year.

annual_operating_days

The mean number of days per year that a mission demand will be placed on an item.

annual_operating_requirement

The estimated or required yearly rate of usage of an item.

annual_operating_time

The total hours that the item under analysis is expected to be operated during a calendar year.

available_man_hour

The total annual number of man-hours for which a SSC is available to perform assigned tasks.

available_quantity

The maximum number of personnel of a given SSC, which will be available to each maintenance unit at a specified level of maintenance,

to perform all tasks required for the item under analysis.

crew_size

The number of personnel assigned to operate a system/equipment.

daily_inspection_mean_elapsed_time

See mean_elapsed_time

daily_inspection_mean_man_hours

See mean_man_hours

end_item_acronym_code (EIAC)

A code that uniquely identifies the system/equipment end item. This code will be assigned by the requiring authority. It will

remain constant throughout the item?s life cycle (e.g., TOW, PATRIOT, Tomahawk, Sparrow, and ALCM).

interoperable_item_commercial_and_government_entity_code

A five-character code assigned by the DLIS to the design control activity or actual manufacturer of an item as contained in

the Cataloging Handbook H4/H8 Series. Assistance in finding CAGE codes may be found at http://www.dlis.dla.mil/cage_welcome.asp

interoperable_item_federal_supply_classification

Federal Supply Class (FSC) is a code identified under the Federal Cataloging/NATO Codification Systems that identifies the

supply classification of an item of supply, an item of production, and/or a homogeneous area of commodities in respect to

their physical or performance characteristics. The first two digits identify the group, and the last two digits of the code

identify the classes within each group. Each class covers a relatively homogeneous area of commodities, in respect to their

physical or performance characteristics, or in the respect that the items included therein are such as are usually requisitioned

or issued together, or constitute a related grouping for supply management purposes. The combination of these four digits

constitutes the Federal Supply Classification.

For applicable codes, see Catalog Handbook H2 or go to http://www.dlis.dla.mil/hcfsch21.asp

interoperable_item_name

An identifying noun with appropriate adjective modifier, as contained in Federal Item Name Directory for Supply Cataloging,

H6-l. Item Names contained in Federal Item Name Directory for Supply Cataloging, H6-l, cannot be abbreviated unless approved

by the requiring authority.

Catalog Handbook H6 may be viewed on line at https://www.dlis.dla.mil/H6/default.asp

interoperable_item_national_item_identification_number

A NIIN provides a unique identification of an item of supply within a specified Federal Supply Classification (FSC). The combination

of the two identifiers (FSC and NIIN) constitutes the National Stock Number (see Appendix B for a complete definition of National

Stock Number and related data). The nine digit NIIN is made up of a two digit NATO Codification Bureau (NCB) code indicating

the assigning country (e.g., the United States uses "00" and "01") and the final seven digits are assigned sequentially and

have no inherent significance. The NIIN relates to one and only one item of supply within the codifying country. It can consist

of one or many "items of production" (i.e., a product of a specific manufacturer) having equivalent "fundamental characteristics."

NOTE: An alphanumeric NIIN is used to document management control or temporarily assigned numbers prior to final NIIN assignment.

Final NIINs are completely numeric.

For applicable codes, see DOD 4100.39-M, Volume 10.

interoperable_item_number_type

A code that specifies whether the item is an interoperability item or a mode of transport item.

|

Code

|

Description

|

|

I

|

Interoperability Item

|

|

M

|

Mode of Transport Item

|

Table — Interoperable Item Number Type

interoperable_item_reference_number

Any number, other than a government activity stock number, used to identify an item of production, or used by itself or in

conjunction with other reference numbers to identify an item of supply. Reference numbers include manufacturer's part, drawing,

model, type, or source controlling numbers; manufacturer's trade name; specification or standard numbers; and, specification

or standard part, drawing, or type numbers (for applicable formats see DOD 4100.39-M). The following precedence for reference

number assignment should be used.

- First Precedent Reference Number. The line item is identified by a government or industry association specifications, drawing,

or standard number, e.g., FED, MIL, JAN, AN, NEMA, SAE, which completely identifies the item including its physical, mechanical,

electrical and dimensional characteristics. (If the government or industry association specification or standard number does

not fully identify the item, then the actual manufacturer's identifying reference number becomes the first precedent reference

number.) If the government or industry specification, drawing, or standard completely identifies the item, at least one additional

reference number (see additional_reference_number_Type) citing a manufacturer or vendor reference number must be provided.

- Second Precedent Reference Number. When the line item is identified as "source control", "altered", or "selected" (MIL-DTL-31000C),

the contractors assigned number is used.

- Third Precedent Reference Number. The item identifying part, drawing, or catalog number of the actual manufacturer that supplies

the item. The manufacturer is the company or government activity exercising design control over the item.

interoperable_item_technical_manual_number

The technical manual, technical order, or manual controlling number assigned by the requiring authority.

labor_rate

The average direct labor rate per hour for an Operations/Maintenance Level. Labor rate is in units of dollars and cents.

logistics_support_analysis_control_number (LCN)

A code that represents a functional or hardware generation breakdown/disassembly sequence of system/equipment hardware including

SE, training equipment, and installation (connecting) hardware. For additional information on assignment of LCN, refer to

the GEIA-HB-0007.

logistics_support_analysis_control_number_type (LCN Type)

A code indicating whether the LCN is representative of either a physical or functional breakdown.

maintenance_level_maximum_time_to_repair

The maximum corrective maintenance downtime within which a specified percent (normally 90 or 95 percent) of all corrective

maintenance actions can be accomplished.

maintenance_level_percentile

See required_percentile

maintenance_level_scheduled_annual_man_hours

The scheduled/unscheduled annual man-hours for a given maintenance level.The sum of the working time of each SSC required

for the performance of a unit of work accumulated for a period of a year.

maintenance_level_unscheduled_annual_man_hours

See maintenance_level_scheduled_annual_man_hours

management_plan

A code entered by the government that directs contractor action on a general management/milestone plan.

mean_elapsed_time

The average time expended, regardless of the number of personnel working simultaneously, required to perform a task scheduled

or unscheduled. This does not include logistics delay time. The time can be predicted or measured, or can be specified as

requirements as depicted below:

Predicted – the estimated time required in the performance of a task expressed in hours and hundredths.

Measured – the actual clock time recorded in the completion of a task from start to finish, expressed in hours and hundredths.

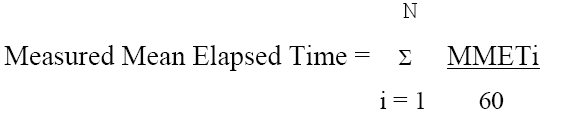

Measured mean elapsed times are calculated by summing mean minute elapsed times for all subtasks. The following formula is

used to calculated measured mean elapsed time:

Figure 6 — Mean Elapsed Time Formula

Where:

N = Total number of subtasks per task

MMETi = Mean minute elapsed time

Required – the maximum time allowed to accomplish a task.

mean_man_hours

The average number of man-hours required to perform a unit of work. The man-hours can be predicted or measured as defined

below, or can be specified as requirements as depicted below:

Predicted – the estimated time required in the performance of a task expressed in hours and hundredths.

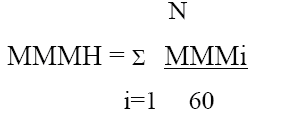

Measured – the actual total clock time recorded in the performance of a task expressed in hours and hundredths. Measured mean

man-hours are calculated only if mean manminute per person identifier are entered for the given task. The following formula

is used to calculate Measured Mean Man-Hours (MMMH) for a given task:

Figure 7 — Mean Man Hours Formula

Where: N = Total number of person ID

MMMi = Mean man-minutes

Required – the maximum man-hours allowed to accomplish a task.

mean_mission_duration

The average length of a mission for an item.

mission_profile_change_mean_elapsed_time

See mean_elapsed_time

mission_profile_change_mean_man_hours

See mean_man_hours

modeling_operations_and_maintenance_level_code

The O/M level associated with supportability modeling information.

Codes that are assigned to indicate the maintenance levels authorized to perform the required maintenance function.

|

Code

|

Name

|

Desription

|

|

C

|

Operator/Crew/Unit-Crew

|

Operations and maintenance that are the responsibility of and performed by the using organization by the system equipment

operator/crew on its assigned equipment. Its phases normally consist of inspecting, servicing, lubricating, adjusting, and

replacing of parts, minor assemblies, and subassemblies.

|

|

O

|

Organizational/On Equipment/Unit-Organizational

|

Maintenance that is the responsibility of and performed by the using organization on its assigned equipment. Its phases normally

consist of inspecting, servicing, lubricating, adjusting, and replacing of parts, minor assemblies and subassemblies.

|

|

F

|

Intermediate/Direct Support/Afloat/Third Echelon/Off Equipment/ Intermediate-Forward

|

The next higher maintenance level after Organizational/On Equipment/Unit-Organization. Titles of "Direct Support" and "Third

Echelon" are associated with ground support forces; "Intermediate" and "Off Equipment" are with nautical and aviation organizations.

Maintenance at this level is the responsibility of, and performed by, designated maintenance activities for direct support

of using organizations. Its phases normally consist of: calibration, repair or replacement of damaged or unserviceable parts,

components, or assemblies; emergency manufacture of nonavailable parts; and technical assistance to using organizations.

|

|

H

|

Intermediate/General Support/Ashore/Fourth Echelon/Intermediate-Rear

|

Maintenance performed on material requiring major overhaul or a complete rebuild of parts, subassemblies and end items, including

manufacture of parts, modification, testing, and reclamation as required. Includes capabilities described in Intermediate/Direct

Support/Afloat/Third Echelon/Off Equipment/Intermediate-Forward.

|

|

G

|

Intermediate/Ashore and Afloat

|

A maintenance level used to identify those maintenance tasks that can be accomplished at the intermediate level both Ashore

and Afloat.

|

|

D

|

Depot/Shipyards

|

The highest level of maintenance activities. Maintenance performed on material requiring major overhaul or a complete rebuild

of parts, subassemblies or end items, including manufacture of parts, modification, testing, and reclamation as required.

Depot maintenance serves to support lower categories of maintenance by providing technical assistance and performing whatever

maintenance is beyond their responsibility. Depot maintenance provides stocks of serviceable equipment by using more extensive

facilities for repair than are available in lower level maintenance activities.

|

|

SRA

|

Specialized Repair Activity

|

A level of maintenance usually characterized by the capability to perform maintenance functions requiring specialized skills,

disciplined quality control, highly sophisticated and expensive special tools, and TMDE. Its phases normally consist of adjustments,

calibration, alignment, testing, troubleshooting, assembly, disassembly, fault isolation, and repair of unserviceable parts,

modules, and printed circuit boards (PCB).

|

Table — Modeling Operations and Maintenance Level Code

modeling_operations_and_maintenance_level_code

See operations_and_maintenance_level_code

modeling_service_designator_code

See service_designator_code

number_of_shops

The number of maintenance locations available to perform repair at each maintenance echelon.

number_of_systems_supported

The average number of systems or end items supported by a maintenance level.

number_operation_locations

The number of locations that will receive and operate the item under analysis.

operational_mean_active_maintenance_downtime

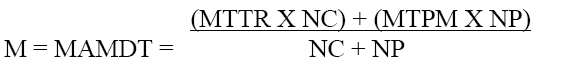

The statistical mean of the individual elapsed times for all maintenance tasks during a specified period of time (clock hours).

The MAMDT, or M, is the weighted average of the mean time to repair (MTTR), and mean preventive maintenance action time (MTPM).

When the number of corrective maintenance actions, (NC), and the number of preventive maintenance actions, (NP), have been

determined for a common reference time, the following formula may be used to calculate MAMDT:

Figure 1 — Operational Mean Active Maintenance Downtime Formula

MAMDT is documented as both technical and operational characteristics. Operational parameters reflect operational reliability

and maintainability characteristics that the system must demonstrate. Only operational mission failures and the resultant

tasks are included (e.g., engine failure will result in mission abort that is both an operational and technical failure).

operational_requirement_indicator

operations_and_maintenance_level_from

See operations_and_maintenance_level_code

operations_and_maintenance_level_to

See operations_and_maintenance_level_code

periodic_inspection_mean_elapsed_time

See mean_elapsed_time

periodic_inspection_mean_man_hours

See mean_man_hours

postoperative_inspection_mean_elapsed_time

See mean_elapsed_time

postoperative_inspection_mean_man_hours

See mean_man_hours

preoperative_inspection_mean_elapsed_time

See mean_elapsed_time

preoperative_inspection_mean_man_hours

See mean_man_hours

reliability_centered_maintenance_logic_utilized

The source document or specification in compliance with which the reliability centered maintenance (RCM) analysis has been

conducted (e.g., NAVAIR 00-25-403).

reliability_operational_requirements_indicator

See operational_requirement_indicator

repair_work_space_cost

The cost in dollars of repair work floor space for a maintenance facility for a specific level of maintenance. It is based

on dollars per square foot per month.

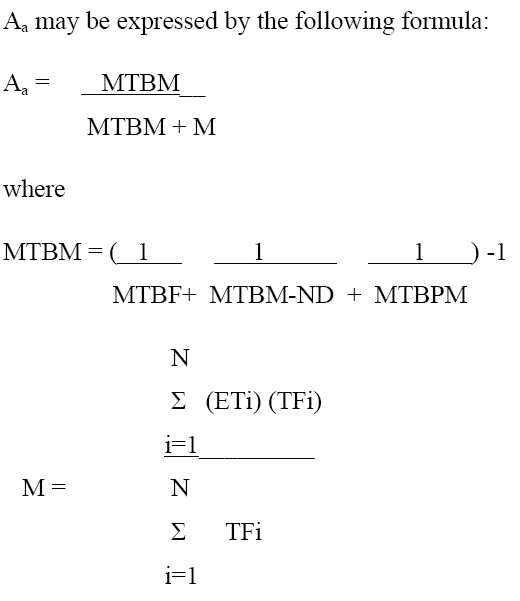

required_achieved_availiability

The probability that, when used under stated conditions in an ideal support environment, a system will operate satisfactorily

at any time. This differs from Inherent Availability only in its inclusion of consideration for preventive action. Aa excludes

supply downtime and administrative downtime. The measurement bases for MTBM and M must be consistent when calculating Aa.

Figure 2 — Required Achieved Availiability Formula

MTBM = Mean time between maintenance

MTBF = Mean time between failure

MTBM-ND = Mean time between maintenance no defect

MTBPM = Mean time between preventive maintenance

M = Mean active maintenance downtime (where corrective and preventive actions are considered)

ETi = Elapsed time for task i

TFi = Task frequency for task i

N = Total number of tasks performed

Note: The measurement bases for MTBF, MTBM-ND, and MTBPM must be consistent when calculating the MTBM parameter.

required_administrative_and_logistics_delay_time

The total time in days the system/equipment is inoperable due to delays in maintenance that are attributable to administration

and logistics.

required_days_of_stock

See repair_work_space_cost

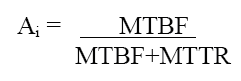

required_inherent_availiability

The probability that, when used under stated conditions in an ideal support environment without consideration for preventive

action, a system will operate satisfactorily at any time. The "ideal support environment" referred to exists when the stipulated

tools, parts, skilled manpower, manuals, SE, and other support items required are available. Ai excludes whatever ready time,

preventive maintenance downtime, supply downtime, and administrative downtime may be required. Ai may be expressed by the

following formula:

Figure 3 — Required Inherent Availiability Formula

Where MTBF = Mean Time Between Failures

MTTR = Mean Time To Repair

NOTE: The measurement bases for MTBF and MTTR must be consistent when calculating Ai.

required_maximum_time_to_repair

See maintenance_level_maximum_time_to_repair

required_mean_time_between_effective_function_failures

An Essential Function Failure (EFF) is an event that results in the loss or operationally unacceptable degradation of an essential

function (an EFF may result in a “Partial Mission Capable” status under wartime conditions or reduce its utility in certain

operations on the battlefield). By definition, all System Aborts are also EFFs. Abort or failure will occur when the system

fails to meet minimum functionality. MTBEFF is an indicator of expected system reliability calculated on a statistical basis

from the known Essential Function Failure rates of various components of the system.

For a system: over a performance measurement/test period, the total operating time of the system divided by the total number

of Essential Function Failures that have occurred during the performance measurement/test period.

For a population of like systems, during a performance measurement/test period, the total operating time of the population

of like systems divided by the total number of Essential Function Failures within the population during the performance measurement/test

period. The total operating time of the population is calculated as the summation of the operating time of every like system

in the population over the performance measurement/test period.

required_mean_time_between_noneffective_function_failures

A Non-essential Function failure (NEFF) is an event that does not result in the operationally significant degradation or loss

of an essential function, but has an obvious indication and a maintenance/corrective action is required to remedy the failure.

A NEFF could be deferred to the next maintenance period.

For a particular interval, the total functional life of a population of an item divided by the total number of NEFFs within

the population during the measurement interval. The definition holds for any measure of life units.

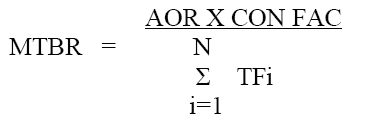

required_mean_time_between_removals

A measure of the system reliability parameter related to demand for logistics support. The total number of operational units

(e.g., miles, rounds, hours) divided by the total number of items removed from that system during a stated period of time.

This term is defined to exclude removals performed to facilitate other maintenance and removals for product improvement. MTBR

may be calculated by the following formula:

Figure 8 — Required Mean Time Between Removals Formula

Where:

AOR = Annual operating requirement

CON FAC = Conversion factor for the LCN/ALC item under analysis

TFi = Task frequency of the "i" applicable maintenance action

N = Total number of applicable maintenance actions

i = Applicable maintenance action (See note below)

Note: For a particular task to be applicable, it must meet ALL of the following criteria:

- It must be either a "remove" or a "remove and replace" task.

- It must be categorized as either an "emergency" or an "unscheduled" task.

- The task must be performed by "operator/crew/unit-crew" or "organizational/on equipment/unit-organizational" or by a maintenance

contact team.

- The task cannot be performed to facilitate other maintenance or for product improvement.

required_mean_time_between_system_aborts

For a system; over a performance measurement/test period, the mean time between system aborts (MTBSA) is the total operating

time of the system divided by the total number of System Abort failures that have occurred during the performance measurement/test

period.

For a population of like systems, during a performance measurement/test period, the total operating time of the population

of like systems divided by the total number of System Abort failures within the population during the performance measurement/test

period. Note: The total operating time of the population is calculated as the summation of the operating time of every like

system in the population over the performance measurement/test period.

A System Abort is an event that results in the loss or degradation of an essential function(s) that renders the system unable

to enter service or causes immediate removal from service, deadlines the platform, or makes it non-mission capable (a system

abort reduces its utility to the point that it is deemed ineffective/unsafe in its role on the battlefield). System abort

also includes those events that create a personal injury related Category I (catastrophic) or II (critical) hazard as defined

in MIL-STD-882.

System abort-mobility failures are those failures (operational hardware, and software) that render (deadline) the basic platform/vehicle

mobility subsystem non-mobile/maneuverable, resulting in unsafe operation, or making it non-mission capable.

A System Abort-Mobility is an event that affects a platform's mobility system(s) and renders the system unable to enter service

or causes immediate removal from service, results in unsafe operation, deadlines the platform, or makes it non-combat capable.

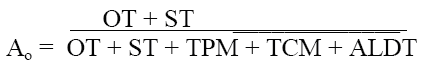

required_operational_availability

The probability that, when used under stated conditions, a system will operate satisfactorily at any time. This differs from

achieved availability in that Ao includes standby time and administrative and logistic delay time. Ao may be expressed by

the following formula:

Figure 5 — Required Operational Availability Formula

Where:

OT = Operating time per calendar year

ST = Standby time

TPM = Total preventive maintenance time per calendar year

TCM = Total corrective maintenance time per calendar year

ALDT = Administrative and logistics delay time spent waiting for parts, maintenance personnel, or transportation per calendar

year

required_operational_mean_time_between_failures

For a particular interval, the total functional life of a population of an item divided by the total number of failures within

the population during the measurement interval. The definition holds for time, rounds, miles, events, or other measure of

life units.

Mean time between failures (MTBF) is documented as both technical and operational characteristics. Technical parameters reflect

the technical reliability that the system/equipment must demonstrate. In determining these parameter values, all failures

and resultant actions to restore the item will be considered (e.g., a broken tail light is a technical, but not operational

characteristic). Operational parameters reflect operational reliability and maintainability characteristics that the system

must demonstrate. Only operational mission failures and the resultant tasks are included (e.g., engine failure will result

in mission abort that is both an operational and technical failure).

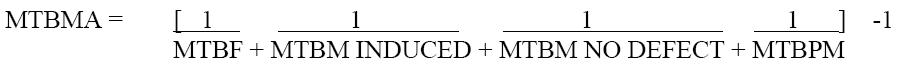

required_operational_mean_time_between_maintenance_actions

A MTBMA representing the supportability requirement/specification MTBMA.

The mean of the distribution of the time intervals between actions or groups of actions required to restore an item to, or

maintain it in, a specified condition. This entry will be

composed of the MTBF, Mean Time Between Maintenance Induced (MTBM INDUCED), Mean Time Between Maintenance No Defect (MTBM

NO DEFECT), and Mean Time Between Preventive Maintenance (MTBPM) values. MTBMA may be calculated by the following formula:

Figure 9 — Required Operational Mean Time Between Maintenance Actions Formula

MTBMA is documented as both technical and operational characteristics. Technical parameters reflect the technical reliability

that the system/equipment must demonstrate. In determining these parameter values, all failures and resultant actions to restore

the item will be considered (e.g., a broken tail light is a technical, but not operational characteristic). Operational parameters

reflect operational reliability and maintainability characteristics that the system must demonstrate. Only operational mission

failures and the resultant tasks are included (e.g., engine failure will result in mission abort that is both an operational

and technical failure).

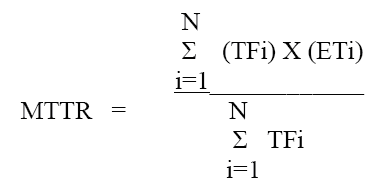

required_operational_mean_time_to_repair

The total elapsed time (clock hours) for corrective maintenance divided by the total number of corrective maintenance actions

during a given period of time. MTTR may be calculated by the following formula:

Figure 4 — Required Operational Mean Time to Repair Formula

Where:

i = On equipment corrective maintenance actions

TFi = Task frequency of "i" on equipment maintenance action

N = Total number of on equipment corrective maintenance actions charged against the LCN/ALC item under analysis

ETi = Mean elapsed time of the "i" on equipment corrective maintenance action

MTTR is documented as both technical and operational characteristics. Technical parameters reflect the technical reliability

that the system/equipment must demonstrate. In determining these parameter values, all failures and resultant actions to restore

the item will be considered (e.g., a broken tail light is a technical, but not operational characteristic). Operational parameters

reflect operational reliability and maintainability characteristics that the system must demonstrate. Only operational mission

failures and the resultant tasks are included (e.g., engine failure will result in mission abort that is both an operational

and technical failure).

required_percentile

The percentage of all corrective maintenance actions that can be accomplished within a specified maximum time to repair.

Maintenance Level Percentile - The percentile within the specified maximum time to

repair for a given operations/maintenance level.

Required Percentile - The percentile associated with the required maximum time to repair.

required_standby_time

The time, in hours per calendar year that a system/equipment is not operating, but is assumed to be operable.

required_technical_mean_time_between_failures

See required_operational_mean_time_between_failures

required_technical_mean_time_between_maintenance_actions

See required_operational_mean_time_between_maintenance_actions

required_technical_mean_time_to_repair

See required_operational_mean_time_to_repair

scheduled_man_hour_per_operating_hour

A code entered by the government that directs contractor action on a general management/milestone plan.

service_designator_code

A single-position code identifying the military service or nonmilitary major governmental agency having jurisdiction over,

or executive management responsibility for, the acquisition.

ship_distance

The geographical distance, in miles, between two points.

ship_time

The number of days from the time a requisition for a spare/repair part is placed with the supply system until the item is

received at the maintenance shop.

skill_specialty_code

Describes the maintenance or operator skill required to accomplish the task.

system_end_item_additional_supportability_considerations_narrative

A narrative description of additional supportability considerations for the item under analysis; includes logistics analysis

modeling considerations that cannot be documented in the discrete supportability data elements. It may include such information

as acceptable models, program or model specific information, etc.

system_end_item_additional_supportability_parameters_narrative

A description of additional supportability parameters that will specify data elements and associated data when discrete fields

are not provided. The documentation should also include the data element title, associated value to be recorded, associated

units, and a description as necessary to define the scope and purpose of the data element and its use.

system_end_item_operational_mission_failure_definition_narrative

A narrative description of the guidelines to be followed to identify operational mission failures for the system/equipment

being documented. Operational mission failures are those failures that, upon occurrence, would prevent the system/equipment

from performing mission

essential functions. Mission essential functions are the minimum operational tasks that the system must be capable of performing

to complete its mission successfully.

technical_mean_active_maintenance_downtime

See operational_mean_active_maintenance_downtime

total_systems_supported

The total number of systems intended for operational use.

turnaround_inspection_mean_elapsed_time

See mean_elapsed_time

turnaround_inspection_mean_man_hours

See mean_man_hours

unscheduled_maintenance_mean_elapsed_time

See mean_elapsed_time

unscheduled_maintenance_mean_man_hours

See mean_man_hours

unscheduled_man_hour_per_operating_hour

See scheduled_man_hour_per_operating_hour

utilization_ratio

The portion of time available for a repairman with a given skill specialty to support the system being documented. (This should

only be used if the repairman works on more than one system.)

Additional terms used in the Help/Information pages.

NOTE These terms are not part of the released specification.