| Business DEX (LOGSA005):— breakdown_element |

Date: 2011/11/17 19:29:27

Revision: 1.30

|

For the purposes of this specification, the following terms apply:

administrative_lead_time

The administrative time (in days) required to prepare, advertise and award a contract for wholesale supply reorder actions.

alternate_logistics_support_analysis_control_number_code

A code used to allow documentation of multiple models of a system/equipment, or alternate design considerations of an item,

using the same LCN breakdown.

NOTE:

- ALC of zero,zero 00 will always be used as the basic system. There are no blanks allowed. ALCs will be assigned from 01

to ZZ in ascending order.

- ALC equates to S1000D Disassembly Code Variant, which is a constituent element of the Data Module Code.

caption

The caption identifies the document represented as a Binary Large Object.

commercial_and_government_entity_city

The manufacturer or government city address.

commercial_and_government_entity_code

A five-character code assigned by the DLIS to the design control activity or actual manufacturer of an item as contained

in the Cataloging Handbook H4/H8 Series. Assistance in finding CAGE codes may be found at http://www.dlis.dla.mil/cage_welcome.asp

commercial_and_government_entity_name

The manufacturer or government name.

commercial_and_government_entity_nation

The manufacturer or government nation address.

commercial_and_government_entity_postal_zone

The manufacturer or government postal zone address.

commercial_and_government_entity_state

The manufacturer or government state address.

commercial_and_government_entity_street

The manufacturer or government street address.

contact_team_delay_time

The time (in hours) required for a contact team to travel from the intermediate maintenance location to the organizational

location.

contract_number

The unique number assigned to the contract in question, by which it can be specifically identified.

contract_team_delay_time

The time (in hours) required for a contact team to travel from the intermediate maintenance location to the organizational

location.

cost_per_reorder_action

The administrative cost in dollars and cents to prepare, advertise, and award a contract/purchase order/basic order agreement

for wholesale supply reorder actions.

cost_per_requisition

The administrative cost in dollars and cents to prepare and submit a requisition for a replenishment spare/repair part.

demilitarization_cost

The estimated cost to demilitarize an item expressed as a percentage of the cost of the item.

discount_rate

The effective rate of return on an investment after adjusting for inflation to discount future costs.

document_code

A code that represents the Material Item Category Code (MICC) and Standard Numbering system (SNS) required for electronic

documentation.

The element is composed of these subfields:

- Material Item Category Code (MICC)

- Standard Numbering System (SNS)

See S1000D.org .

document_code_alternate_logistics_support_analysis_control_number_code

See alternate_logistics_support_analysis_control_number_code

document_code_logistics_support_analysis_control_number

A code that represents a functional or hardware generation breakdown/disassembly sequence of system/equipment hardware including

SE, training equipment, and installation (connecting) hardware. For additional information on assignment of LCN, refer to

the GEIA-HB-0007.

document_code_logistics_support_analysis_control_number_type

document_file_extension

The file extension of the document, thumbnail, or drawing image

document_id

A designation assigned to a particular drawing or document by the authoritive source for identification purposes. The document

id may include numbers, letters, and dashes

document_identifier

A code that identifies the match conditions resulting from prescreening reference number searches outlined in DOD 4100.39-M,

Volume 10, Table 105. These codes are commonly referred to as Match Indicator Codes

drawing

A Binary Large Object containing any image or document

end_item_acronym_code

A code that uniquely identifies the system/equipment end item. This code will be assigned by the requiring authority. It will

remain constant throughout the item’s life cycle (e.g., TOW, PATRIOT, Tomahawk, Sparrow, and ALCM).

estimated_salvage_value

The estimated end of life salvage value expressed as a percentage of the cost of the item.

functional_alternate_logistics_support_analysis_control_number_code

See physical_alternate_logistics_support_analysis_control_number_code

functional_logistics_support_analysis_control_number

See physical_logistics_support_analysis_control_number

functional_logistics_support_analysis_control_number_type

See physical_alternate_logistics_support_analysis_control_number_code

graphic_source_identification

A code, identified by the project, that describes non-textual information. This unique identifier facilitates configuration

and hypertext linking within data modules. The code application following shows part of the Illustration Control Number (ICN).

Further details of the ICN may be found in S1000D.

Data is allocated as follows:

|

Length

|

Type

|

Description

|

|

1

|

string

|

Responsible Partner Company

|

|

8

|

string

|

Originator Code – The CAGE code of the originator of illustration including the User Nation Code

|

|

5

|

string

|

Illustration Sequence Number (ISN) - The illustration sequence number for each project starting with 00001 for each company

|

|

1

|

string

|

Illustration Code Variant - The illustratration code variant is a single alpha character that identifies the variants of a

basic illustration. Code A shall identify a basic illustration and subsequent letters identify subsequent variants.

|

|

2

|

string

|

Illustration Issue Number(ISS) - The Illustration Issue Number start with 01 and is incremented each time the illustration

is updated.

|

|

1

|

string

|

Security Classification (SEC) - The Security Classification of the illustration is identified by one character

|

|

15

|

string

|

Reserved for Project Use

|

Table — Graphic Source Identification

holding_cost_percentage

A percentage of inventory value to account for storage, loss, obsolescence, and interest cost incurred as a result of maintaining

inventory.

holding_cost_percentage

A percentage of inventory value to account for storage, loss, obsolescence, and interest cost incurred as a result of maintaining

inventory.

initial_bin_cost

The initial cost, in whole dollars, of entering an item into the retail supply system. This includes the administrative cost

of setting up a bin for the item at the wholesale supply point.

initial_cataloging_cost

The initial cost, in whole dollars, of entering a new item into the wholesale supply system. This is generally considered

to be the cost of screening the item and assigning an NSN.

interest_rate

The rate of interest used to account for the time value of money when performing cost analyses and converting expenditures

over a period of time to a common point.

inventory_storage_space_cost

The cost of storing repairable item inventory at the designated maintenance facility. This cost is in dollars per cubic foot

per month.

labor_rate

The average direct labor rate per hour for an Operations/Maintenance Level. Labor rate is in units of dollars and cents.

loading_factor

A factor that is applied to the hourly and annual manpower costs to account for overhead, benefits, permanent change of station

moves, hazardous duty, etc.

logistics_support_analysis_control_number

logistics_support_analysis_control_number_indenture_code

A single-position code that reflects the relationship of the item to the total system. The LCN Indenture Code depicts an item's

relationship based upon the assigned LCN, not to a subordinate, provisioned end item.

logistics_support_analysis_control_number_nomenclature

An identifying noun with an appropriate adjective modifier identifying the LCN item. When using the modified classical LCN

assignment method, then "REPAIR PARTS" is used to identify an LCN representing more than one reference number and CAGE combination.

logistics_support_analysis_control_number_structure

A number signifying the number of indenture levels represented by the LCN when the LCNs are assigned using the classical or

modified classical assignment method. The first digit of the LCN structure is the number of digits used in the LCN to identify

the first indenture level. The second digit is the number of digits used to identify the second indenture level, etc.

logistics_support_analysis_control_number_type

A code that represents a functional or hardware generation breakdown/disassembly sequence of system/equipment hardware including

SE, training equipment, and installation (connecting) hardware. For additional information on assignment of LCN, refer to

the GEIA-HB-0007.

maintenance_procedure_disassembly_code

A code that identifies the breakdown sequence of an assembly, below the standard numbering system (SNS) level, to which maintenance

and descriptive information applies. This is a constituent of the S1000D Data Module Code. It includes codes 00 to 99 ;

then A1 to A9 , and so on. Omit the characters I and O .

maintenance_procedure_identifier

A code used to uniquely identify a maintenenace procedure.

maintenance_procedure_information_code

A code used to identify the type of information in a data module. Refer to the S1000D Standard at S1000D.org.

maintenance_procedure_information_code_variant

A code used to identify different data modules that are applicable to the same subject and type of data. Refer to the S1000D

Standard at S1000D.org.

maintenance_procedure_item_location_code

A code that identifies where the task/operation will be performed. The code is a constituent of the S1000D Data Module Code.

|

Code

|

Desription

|

|

A

|

Information related to items installed on the product

|

|

B

|

Information related to items installed on an engine or major assembly removed from the product

|

|

C

|

Information related to items on the bench. In this context, it does not matter whether the item has been removed from the

product

|

|

D

|

Information related to all three locations A, B, and C. No other combinations are allowed

|

|

T

|

Information related to training-only data modules

|

Table — Maintenance Procedure Item Location Code

maintenance_procedure_maintenance_interval

The number of operational units (e.g., rounds, miles, hours) between preventive maintenance derived as an outcome of the

RCM analysis.

maintenance_procedure_task_type

A code that categorizes a maintenance task as corrective, a preventive based on calendar time, or a preventive based on a

rate of use.

|

Code

|

Desription

|

|

C

|

Corrective

|

|

P

|

Preventive (calendar)

|

|

U

|

Preventive (usage)

|

Table — Maintenance Procedure Task Type

maintenance_procedure_title

The title of a maintenance procedure.

modeling_operations_and_maintenance_level_code

The O/M level associated with supportability modeling information.

Codes that are assigned to indicate the maintenance levels authorized to perform the required maintenance function.

|

Code

|

Name

|

Desription

|

|

C

|

Operator/Crew/Unit-Crew

|

Operations and maintenance that are the responsibility of and performed by the using organization by the system equipment

operator/crew on its assigned equipment. Its phases normally consist of inspecting, servicing, lubricating, adjusting, and

replacing of parts, minor assemblies, and subassemblies.

|

|

O

|

Organizational/On Equipment/Unit-Organizational

|

Maintenance that is the responsibility of and performed by the using organization on its assigned equipment. Its phases normally

consist of inspecting, servicing, lubricating, adjusting, and replacing of parts, minor assemblies and subassemblies.

|

|

F

|

Intermediate/Direct Support/Afloat/Third Echelon/Off Equipment/ Intermediate-Forward

|

The next higher maintenance level after Organizational/On Equipment/Unit-Organization. Titles of "Direct Support" and "Third

Echelon" are associated with ground support forces; "Intermediate" and "Off Equipment" are with nautical and aviation organizations.

Maintenance at this level is the responsibility of, and performed by, designated maintenance activities for direct support

of using organizations. Its phases normally consist of: calibration, repair or replacement of damaged or unserviceable parts,

components, or assemblies; emergency manufacture of nonavailable parts; and technical assistance to using organizations.

|

|

H

|

Intermediate/General Support/Ashore/Fourth Echelon/Intermediate-Rear

|

Maintenance performed on material requiring major overhaul or a complete rebuild of parts, subassemblies and end items, including

manufacture of parts, modification, testing, and reclamation as required. Includes capabilities described in Intermediate/Direct

Support/Afloat/Third Echelon/Off Equipment/Intermediate-Forward.

|

|

G

|

Intermediate/Ashore and Afloat

|

A maintenance level used to identify those maintenance tasks that can be accomplished at the intermediate level both Ashore

and Afloat.

|

|

D

|

Depot/Shipyards

|

The highest level of maintenance activities. Maintenance performed on material requiring major overhaul or a complete rebuild

of parts, subassemblies or end items, including manufacture of parts, modification, testing, and reclamation as required.

Depot maintenance serves to support lower categories of maintenance by providing technical assistance and performing whatever

maintenance is beyond their responsibility. Depot maintenance provides stocks of serviceable equipment by using more extensive

facilities for repair than are available in lower level maintenance activities.

|

|

SRA

|

Specialized Repair Activity

|

A level of maintenance usually characterized by the capability to perform maintenance functions requiring specialized skills,

disciplined quality control, highly sophisticated and expensive special tools, and TMDE. Its phases normally consist of adjustments,

calibration, alignment, testing, troubleshooting, assembly, disassembly, fault isolation, and repair of unserviceable parts,

modules, and printed circuit boards (PCB).

|

Table — Modeling Operations and Maintenance Level Code

modeling_service_designator_code

A single-position code identifying the military service or nonmilitary major governmental agency having jurisdiction over,

or executive management responsibility for, the acquisition.

|

Code

|

Desription

|

|

A

|

Army

|

|

F

|

Air Force

|

|

Y

|

Coast Guard

|

|

T

|

Federal Aviation Administration (FAA)

|

|

S

|

National Security Agency

|

|

N

|

Navy

|

|

M

|

Marine Corps

|

|

X

|

All military

|

|

J

|

FAA/all military

|

|

O

|

Other

|

Table — Modeling Service Designator Code

number_of_shops

The number of maintenance locations available to perform repair at each maintenance echelon.

operation_level

The number of days worth of stock intended to sustain normal operations during the interval between receipt of replenishment

shipment and submission of subsequent replenishment requisition. Does not include either safety level or order ship time quantities.

operation_life

The number of years the item is expected to be in service.

personnel_turnover_rate_civilian

The portion of personnel, expressed in percent per year, leaving their SSC that will be replaced by new personnel requiring

training.

|

Code

|

Type

|

|

Military

|

The military turnover rate

|

|

Civilian

|

The civilian turnover rate

|

Table — Personnel Turnover Rate Civilian

personnel_turnover_rate_military

See personnel_turnover_rate_civilian

physical_alternate_logistics_support_analysis_control_number_code

See alternate_logistics_support_analysis_control_number_code

physical_logistics_support_analysis_control_number

A code that represents a functional or hardware generation breakdown/disassembly sequence of system/equipment hardware including

SE, training equipment, and installation (connecting) hardware. For additional information on assignment of LCN, refer to

the GEIA-HB-0007.

physical_logistics_support_analysis_control_number_type

A code indicating whether the LCN is representative of either a physical or functional breakdown.

productivity_factor

This factor is used to account for nonproductive time and has the effect of increasing manpower requirements for performing

maintenance. For instance, if the worker’s scheduled work day is 8 hours, he may only be available for 6 hours to do maintenance

due to other duty assignments, in this case, the productivity factor is ((8-6)/8) + 1 = 1.25.

quantity_per_end_item_calculation_option_code

A code (1, 2, or 3) that identifies the type of calculation used for the quantity_per_end_item_Type.

Note: The Greek "Σ" or SIGMA represents the mathematical symbol for a series summation while the symbol "Τ" or TAU is the

mathematical expression for a series multiplication.

Option 1. The quantity per equipment or end item shall be entered only on the first appearance of the line item on the list.

Subsequent appearances of the same item should be indicated by printing the letters "REF" in positions 1-3 to indicate that

the total number of uses of the item in the equipment or end item has previously been listed.

Note: This option can only be used with Option 1 QTY/ASSY.

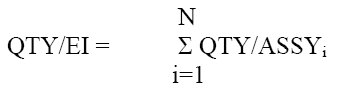

The following formula applies to option 1:

Figure 1 — Quantity Per End Item Calculation Code Option 1

Where:

N = Number of applications for unique part

i = Application of unique part

M = Number of indenture levels

j = Indenture level of application

Option 2. The QTY/EI shall be entered only on the first appearance of the item on the list. Subsequent appearances of the

same assembly or subassembly should be indicated by printing "REFX" in positions 1-4. Subsequent appearances of the same repair

part (i.e., a part that has no lower indentured parts) should be indicated by printing the letters "REF" in positions 1-3.

This option can only be used with option 2, QTY/ASSY. Examples of provisioning lists with a single assembly breakdown using

the option 2 QTY/ASSY follow: Note that a separate application (PLISN and LCN) is required for each identical item in the

same NHA.1.

|

RD

|

Reference No.

|

QTY-ASSY

|

QTY-EI

|

|

1A1

|

ABC

|

0003

|

0003

|

|

1A1

|

R1

|

0003

|

0006

|

|

1A1

|

R2

|

0003

|

REF

|

|

1A1

|

MP2

|

0006

|

0006

|

|

1A2

|

ABC

|

0000

|

REFX

|

|

1A3

|

ABC

|

0000

|

REFX

|

Table — For reference designation (RD) oriented equipment.

|

Indenture Code

|

Reference No.

|

QTY-ASSY

|

QTY-EI

|

|

B

|

ABC

|

0001

|

0003

|

|

C

|

PDQ

|

0003

|

0006

|

|

C

|

PDQ

|

0003

|

REF

|

|

C

|

XYZ

|

0006

|

0006

|

|

B

|

ABC

|

0001

|

REFX

|

|

B

|

ABC

|

0001

|

REFX

|

Table — For nonreference designation oriented equipment

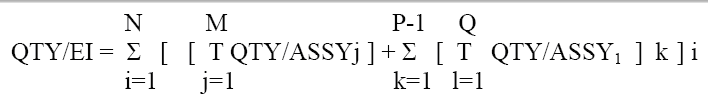

The following formula applies to option 2:

Figure 2 — Quantity Per End Item Calculation Code Option 2

Where:

N = Number of applications for unique part

i = Application of unique part

Option 3. The QTY/EI shall be entered only on the first appearance of the line item on the list for system/equipment for which

the list is prepared, and should equal the total number of appearances of the item in that system/equipment (all appearances

of an item may not appear on the list). Subsequent appearances of the same assembly or subassembly should be indicated by

printing "REFX" in position 1-4. Subsequent appearances of the same repiar part (i.e., a part that has no lower indentured

parts) should be indicated by printing the letters "REF" in positions 1-3. This option can only be used with option 3 of the

QTY/ASSY.

The following formula applies to option 3:

Figure 3 — Quantity Per End Item Calculation Code Option 3

Where:

N = Number of applications of unique part (first appearance of NHA only)

i = Application of unique part

M = Number of indenture levels

j = Indenture level of application at first appearance

P = Number of applications of unique assembly containing unique part

k = Application of unique part (other than first appearance of a higher assembly)

Q = Number of indenture levels at assembly application (other than first appearance of a higher assembly)

l = Indenture level of application (other than first appearance of a higher assembly)

Note: The first product and summation in this formula are performed against the first appearance of an item. These applications

are documented in the LSAR hardware breakdown. The second product and summation are performed against subsequent appearances

of an item that are not documented in the LSAR (e.g., will not appear on a provisioning list). These item applications are

identified by the first appearance of the item in an assembly (either NHA or higher) and the reference number of the higher

assembly containing the unique part appearing in multiple applications.

recurring_bin_cost

Recurring administrative cost expressed in whole dollars of maintaining a bin for an item in the retail supply system for

one year.

recurring_cataloging_cost

Recurring administrative cost expressed in whole dollars of maintaining an item in the wholesale supply system for one year.

reference_maintenance_procedure_identifier

A code used to uniquely identify a maintenenace procedure.

reliability_availability_and_maintainability_indicator

repair_work_space_cost

The cost in dollars of repair work floor space for a maintenance facility for a specific level of maintenance. It is based

on dollars per square foot per month.

required_days_of_stock

The number of days required to operate a maintenance facility at a specific level of maintenance without resupply of resources

depleted during daily maintenance.

retail_stockage_criteria

The number of demands per year required to allow stockage of an item.

safety_level

The number of days of stock in addition to operating level to compensate for unexpected demands, repair cycle times, pipeline,

and procurement lead time, and unforeseen delays.

sectionalized_item_transportation_indicator

sequenced_task_end_item_acronym_code

A code that uniquely identifies the system/equipment end item. This code will be assigned by the requiring authority. It

will remain constant throughout the item’s life cycle (e.g., TOW, PATRIOT, Tomahawk, Sparrow, and ALCM).

sequenced_task_logistics_support_analysis_control_number

A code that represents a functional or hardware generation breakdown/disassembly sequence of system/equipment hardware including

SE, training equipment, and installation (connecting) hardware. For additional information on assignment of LCN,

refer to the GEIA-HB-0007.

sequenced_task_logistics_support_analysis_control_number_type

serial_number_from

AA two-part sequence identifying the range of serial numbers of a specific group of end items or basic systems to which the

item applies. Consists of the following elements:

- From - The beginning serial number in the range of serial numbers defined by Serial Number Effectivity

- To - The ending serial number in the range of serial numbers defined by Serial Number Effectivity

serial_number_system_alternate_logistics_support_analysis_control_number_code

See alternate_logistics_support_analysis_control_number_code

serial_number_system_logistics_support_analysis_control_number

A code that represents a functional or hardware generation breakdown/disassembly sequence of system/equipment hardware including

SE, training equipment, and installation (connecting) hardware. For additional information on assignment of LCN, refer to

the GEIA-HB-0007.

serial_number_system_logistics_support_analysis_control_number_type

serial_number_to

Same defination at serial_number_from.

serial_number_usable_on_code

A code that indicates the configuration of a system/end item based on serial numbers of the system/end item. Codes will be

assigned in sequence A-Z, then AA-ZZ, followed by AAA-ZZZ . A blank SN UOC indicates full effectively/applicability. A statement

shall be attached to the provisioning list defining SN UOC usage.

An example of the use of this option is as follows:

|

Model

|

Designator

|

UOC Serial Number

|

|

J-l00-54

|

A

|

56251-56300

|

|

J-l00-54

|

B

|

56301-56500

|

|

J-l00-54

|

C

|

56501-56750

|

|

J-l00-54

|

D

|

56751, 56755, 57801,57802

|

|

J-l00-54

|

E

|

56752, 56790, 57000

|

|

------

|

etc.

|

------

|

|

J-100-60

|

Z

|

59251-59500

|

|

J-l00-65

|

AA

|

57501-57800

|

|

J-l00-65

|

AB

|

57901-58000

|

|

------

|

etc.

|

------

|

|

J-l00-95

|

BZ

|

59501-59575

|

|

J-l00-95

|

CA

|

59501-59575

|

Table — Serial Number Usable on Code

support_of_support_equipment_cost_factor

A decimal value that expresses the cost factor for supporting SE. This factor is derived from the ratio of the yearly SE costs

to the SE unit costs.

system_end_item_identifier

A code that signifies whether the LCN represents a system, end item, or not a system/end item. A system or end item is an

item capable of independent operation, or is a class or group of equipments that is managed and provisioned under a separate

Provisioning Contract Control Number.

|

Code

|

Description

|

|

S

|

System

|

|

E

|

End Item

|

|

N

|

Not a System/End Item

|

Table — System End Item Identifier

system_end_item_item_designator_code

A part of nomenclature that provides a method for identifying equipment, usually by broad performance and use characteristics

and general configuration. It is a data chain consisting of all or part of the data elements type, model, and series designators,

in that order. A suffix may be added for use with the Joint Electronics Type Designation System. Instructions for coding the

type, model, and series designators consist of the following subfields:

- Type designator string 7 -- A broad categorization of equipment based upon function or use

- Model designator string 10 -- Identifies equipment within a particular type designator having essentially the same performance

characteristics

- Series designator string 2 -- Identifies equipment within a particular model designator having the same basic design, but

not necessarily the same configuration.

- Suffix designator string 7 -- Supplemental information used with type, model, and series designators for items using the Joint

Electronics Type Designation System. Instructions for coding suffix designator can be found in the following publications

See also MIL-HDBK-1812 and MIL-STD-196E

system_end_item_provisioning_contract_control_number

The PCCN of the system/end item as a model (A indenture code) item. A number assigned by the requiring authority to identify

a specific contract or a group of end items/components that can have many configurations/models. NOTE: The first position

shall be alphabetic and will identify the applicable military service/agency provisioning designator having responsibility

for the item(s) being processed. First position codes are as follows:

|

Code

|

Description

|

|

A-I

|

Army

|

|

J

|

National Security Agency

|

|

K

|

Federal Aviation Administration

|

|

L-M

|

Marine Corps

|

|

N-R

|

Navy

|

|

S-X

|

Air Force

|

|

Y

|

Coast Guard

|

|

Z

|

Defenese Logistics Agency

|

Table — System End Item Provisioning Contract Control Number

system_end_item_provisioning_list_item_sequence_number

A sequentially assigned value for all items contained in the system/equipment breakdown. The codes are as follows: AAAA through

9999. The numbering of line items shall begin with AAAA and progress through 9999, or as specified by the requiring authority.

- When an item is contained in both a common and bulk items list (CBIL) and a provisioning parts list (PPL), it may be assigned

the same PLISN on both lists. When an item appears on a CBIL only, the PLISN may be unique (i.e., will not duplicate any PLISN

in the PPL).

- The fifth position of the PLISN shall be used to indicate additions to the breakdown. For this purpose, the letters A through

Z, inclusive and the numbers 0 through 9, inclusive, shall be used starting with the letter A for the first addition and continuing

sequentially through the alphabet and then through the numeric characters. An add entry, identified by the letters A, B, C,

etc., in the fifth position of the PLISN, is sequenced for inserting new items in the provisioning list either as a first

or subsequent (same as) item entry, which will be used for either regular additions or replacement items. If the item listed

is not an addition, the fifth position shall be left blank.

system_end_item_quantity_per_assembly

The total number of times a line item is used in the assembly of which it is a part. If the quantity is unknown or cannot

be determined, specify the quantity by "V" (variable) or as specified by the provisioning activity.

Note:

- Option 1. The contractor shall enter the total number of times the line item is used in the assembly of which it is a part

and QTY/EI can only be used with Option 1 QTY/ASSY

- Option 2. For provisioning parts lists (PPLs) in reference designation format, enter the number of times the item appears

at the location in the end item documented by the PPL. When an assembly is broken down by individual piece parts at its first

appearance, the quantity for the assembly and for each piece part at each location shall be the number of times it appears

in the assembly multiplied by the number of appearances of the assembly in the end item. For other provisioning lists under

option 2, the QTY/ASSY can be considered as the QTY/EI.

- Option 3. The contractor shall enter the total number of times the line item is used in the assembly of which it is a part.

An assembly only needs to be broken out to its piece parts at its first occurrence on a list. Subsequent appearances of the

same assembly shall not be broken out.

system_end_item_quantity_per_end_item

The quantity per end item of the system/end item as a model (A indentured) item. Exception: If the item does not have a Next

Higher Assembly, the Quantity per End Item should be blank.

The total number of times the line item is used in the complete system/equipment. If the quantity is unknown or cannot be

determined specify the quantity by "V" (variable) or as specified by the provisioning activity.

There are three selections used in the calculation of the Quantity per End Item. A description of these options is found in

the description of the selection code selection code quantity_per_end_item_calculation_option_code_Type.

system_end_item_type_of_change_code

This block, which is blank on initial submissions of provisioning data, shall be used as a

type of change code to indicate deletions, modifications, typographical errors, quantity

changes (increase, de crease), and limited part applications as follows:

|

Code

|

Desription

|

|

D

|

Indicates a deleted item

|

|

G

|

Deletion of a data element

|

|

L

|

Item is replaced during production and support of the old part may be required for prior production quantities

|

|

M

|

Indicates a modified item. Required to identify entries for those items changed as a result of either administrative or engineering

requirements (not for initial entry of NSN) before or during production.

|

|

Prime contractor's reference number

|

|

Commercial and government entity code

|

|

Manufacturer's reference number

|

|

Item name

|

|

Other data elements as may be subsequently defined, wherein the hardware is not affected

|

Table — Examples

|

|

Q

|

Used to make quantity field changes

|

|

T

|

Used to make a typographical error correction (not automatically assigned)

|

Table — System End Item Type of Change Code

task_remarks

A very brief description of peculiar or unusual maintenance requirements associated with a specific task. These statements

are included in section IV of the maintenance allocation chart (MAC).

task_remarks_reference_code

A code used to uniquely identify a specific remark. Once associated with a remark, a code may not be associated with any

other remark, regardless of the LCN and Task Code. Once assigned, the same code shall be used to identify subsequent occurrences

of that remark, regardless of the LCN and Task Code.

task_sequence_number

A four position number that indicates the sequence of a procedural step for a task. The number begins with 1 and ends with

9999.

technical_manual_functional_group_code

An alphanumeric code used to identify a particular system, subsystem, component/assembly, or part of the system/equipment

used for development of maintenance allocation charts, narrative technical manuals, and repair parts and special tools lists.

Codes will be as specified by the requiring authority.

technical_manual_number

The technical manual, technical order, or manual controlling number assigned by the requiring authority.

thumbnail

A reduced-size version of the image in the same row.

thumbnail_file_extension

The file extension of the document, thumbnail, or drawing image

transportation_cost

The cost per pound per mile, expressed in dollars and cents, for transportation of material.

transportation_end_item_indicator

A code that signifies whether the LCN represents a system/end item requiring transportation requirements documentation.

|

Code

|

Desription

|

|

Y

|

System/End Item requires transportation documentation

|

|

N

|

System/End Item does not require documentation.transportation

|

Table — Transportation End Item Indicator

type_acquisition

The type of acquisition for the system/equipment.

|

Code

|

Type

|

|

R

|

Research, Development Test and Evaluation

|

|

N

|

Nondevelopmental Item

|

|

P

|

Product Improvement Item

|

|

C

|

Commercial Construction Equipment

|

Table — Type Acquisition

type_of_supply_system_code

usable_on_code

A code that indicates the configuration of a system/equipment on which the item under analysis is used. The UOC represents

only one configuration/model of equipment. It is a one, two, or three-character alphanumeric entry with guidance for UOC assignment

provided by the requiring authority. When an item is applicable to multiple equipment configurations, multiple UOCs representing

each configuration are assigned to the item.

work_area_code_zone

A code that identifies a work area zone. Zones shall be identified by a code consisting of up to ten characters. This equates

to S1000D ZONE.

Additional terms used in the Help/Information pages.

NOTE These terms are not part of the released specification.