Template:— inventory_item_demand (invntry_itm_dmnd)

Context:— UK_Defence |

Date: 2010/03/18 11:41:29

Revision: 1.8

|

This section specifies the template inventory_item_demand.

NOTE

The template has been defined in the context of

UK_Defence.

Refer to the business context for details of related templates.

NOTE

An explanation of a template and the associated instantiation path is

provided in the

Template overview

section.

This template describes how to represent a demand/request for an inventory item.

A Inventory Item Demand is the means to represents a demand/request for an inventory item.

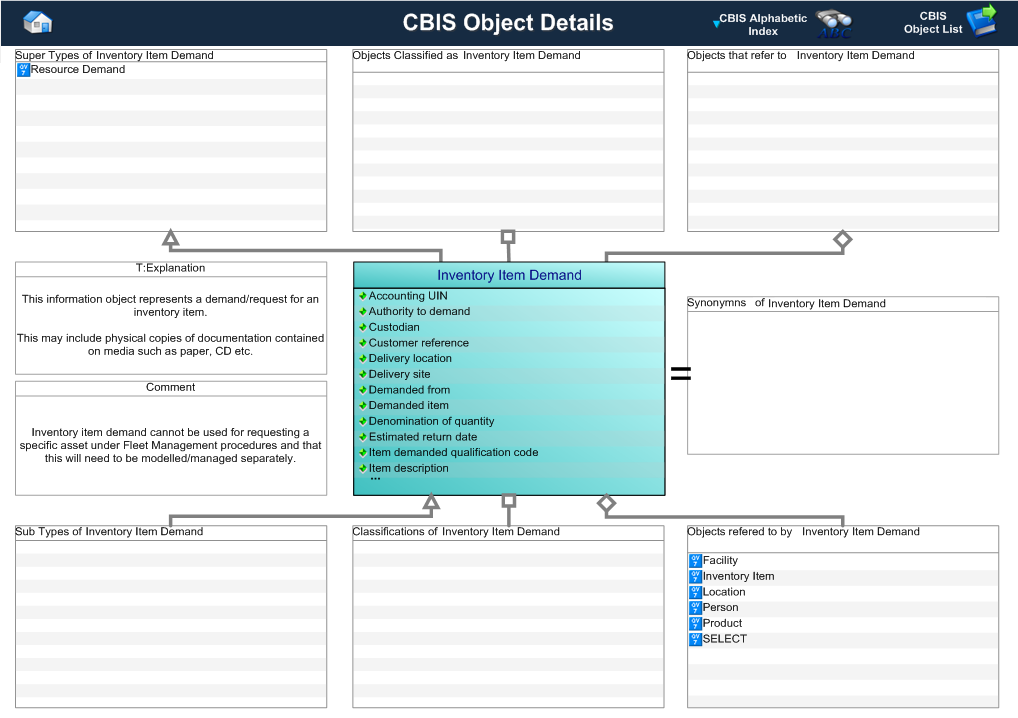

Figure 1 — Graphical Representation for Business Object inventory_item_demand

inventory_item_demand

The definition of an inventory_item_demand object is:

This information object represents a demand/request for an inventory item.

This may include physical copies of documentation contained on media such as paper, CD etc

|

Attribute name

|

Attribute description

|

Attribute type

|

Optionality

|

| Accounting UIN |

This is the unit identification number against which the demand will be charged. |

intrinsic |

Optional |

| Authority to demand |

This is the authority to demand the related inventory item. |

intrinsic |

Mandatory |

| Custodian |

This is a reference to the custodian of the inventory item when delivered.

This may be represented by the Armament Loan Record (ALR) or Permanent Loan Record (PLR) designation.

|

Relationship to Person |

Optional |

| Customer reference |

This is a reference number provided by the organization demanding the item.

Example:

DE&S Project Code,

Special Projects Code,

RN Main Equipment Type,

Contract Number,

Liability Number,

Special Operations Code,

Epecial Exercise Code.

|

intrinsic |

Optional |

| Delivery location |

This is a reference to the delivery facility or location. |

Relationship to Facility or Location |

Optional |

| Delivery site |

This is a reference to a site within the demanding organization. |

Relationship to Location |

Mandatory |

| Demanded from |

This is the identifier of the unit from which the item is demanded. |

intrinsic |

Mandatory |

| Demanded item |

This is a reference to the specification of the item being demanded. |

Relationship to Inventory Item |

Mandatory |

| Denomination of quantity |

This is the denomination quantity of the item being demanded. |

intrinsic |

Mandatory |

| Estimated return date |

This is the date on which it is estimated that the demanded item will be returned to the issuer. |

intrinsic |

Optional |

| Item demanded qualification code |

This is an item demand qualification code. The values are numerical codes ranging from 0 to 9.

It allows for alternative items of supply to be provided.

|

intrinsic |

Optional |

| Item description |

This is the textual description of the demanded item. It may be used to describe the Item in the absence of an NSN.

Any details of item that will help in identifying it will be used, such as description and associated equipment

type or Manufacturer’s Part Number, known stockist, stockist’s address or other contact details, WESPIL No, BR 2525 Ref No

(Part, Folio, and Index), PIL or IPC (Alphanumeric of PIL/IPC also to be given). Manufacturer’s Part Number to be used if

no other information available or if it might help identification.

|

intrinsic |

Mandatory |

| Item name |

This is the name of the item being demanded. |

intrinsic |

Mandatory |

| Point of contact |

This is the point of contact for the demand. |

Relationship to Person |

Optional |

| Priority code |

This is the priority of the demand.

See the Standard Priority Codes specified in JSP 886, Volume 3, Part 1, Section 2.

|

intrinsic |

Mandatory |

| Quality demanded qualification code |

This is the quantity demanded qualification code of the demand. It allows or prevents reduced or staged quantities to be delivered. |

intrinsic |

Optional |

| Reason for demand code |

This is a code to classifiy the reason for demand or justification.

See Reason For Demand (RFD) Codes in Appendices 12-14 JSP 886 Vol 3 Pt1.

|

intrinsic |

Mandatory |

| Related return item |

This is the reference to the item that is being replaced by the item demanded.

This covers the Army AFG 1043 or RAF F731 form requirements.

|

Relationship to Product |

Optional |

| Remarks |

This is for specifications of any special requirements, including packaging, handling, transportation etc.

This may for example, include justification for air freighting of items not usually transported by air.

|

intrinsic |

Optional |

| Required delivery date |

This is the required delivery date for the demanded item. |

intrinsic |

Mandatory |

| Stock location |

This is a reference to the location where the stock will be held when delivered. |

Relationship to Facility |

Optional |

| Theatre delivery code |

This is the theatre into which the demanded item is required to be delivered.

This is required so that supply chain pipeline times can be calculated for performance monitoring.

|

intrinsic |

Mandatory |

Table 1 — inventory_item_demand attribute details

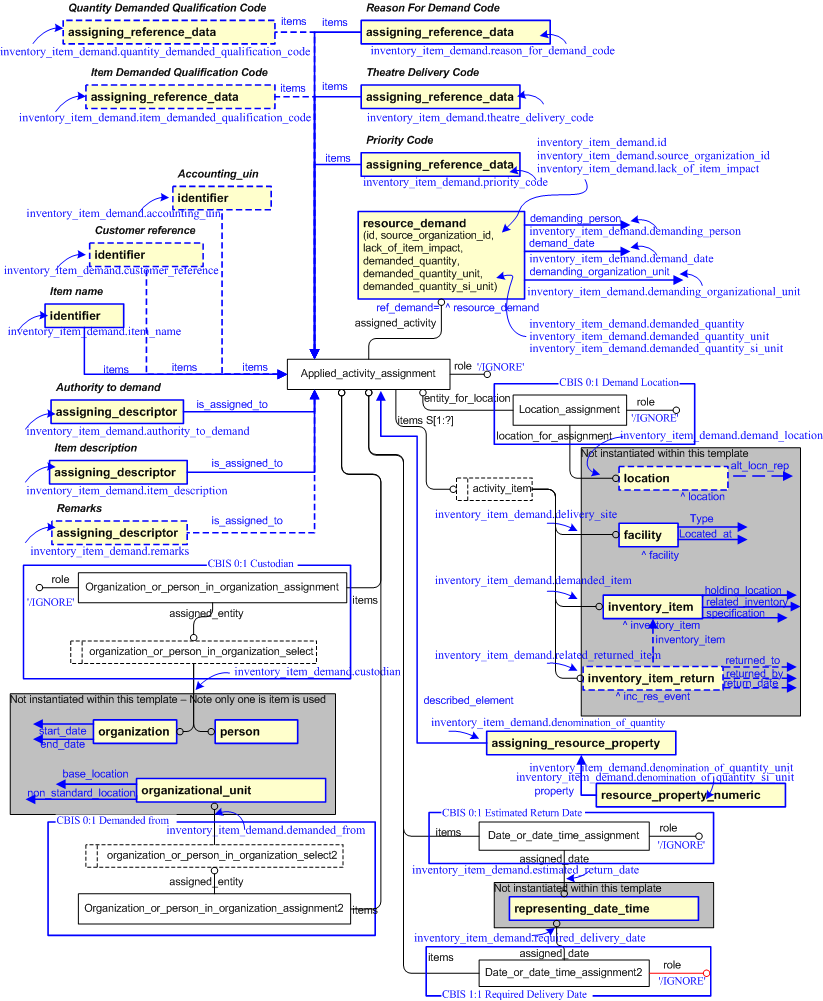

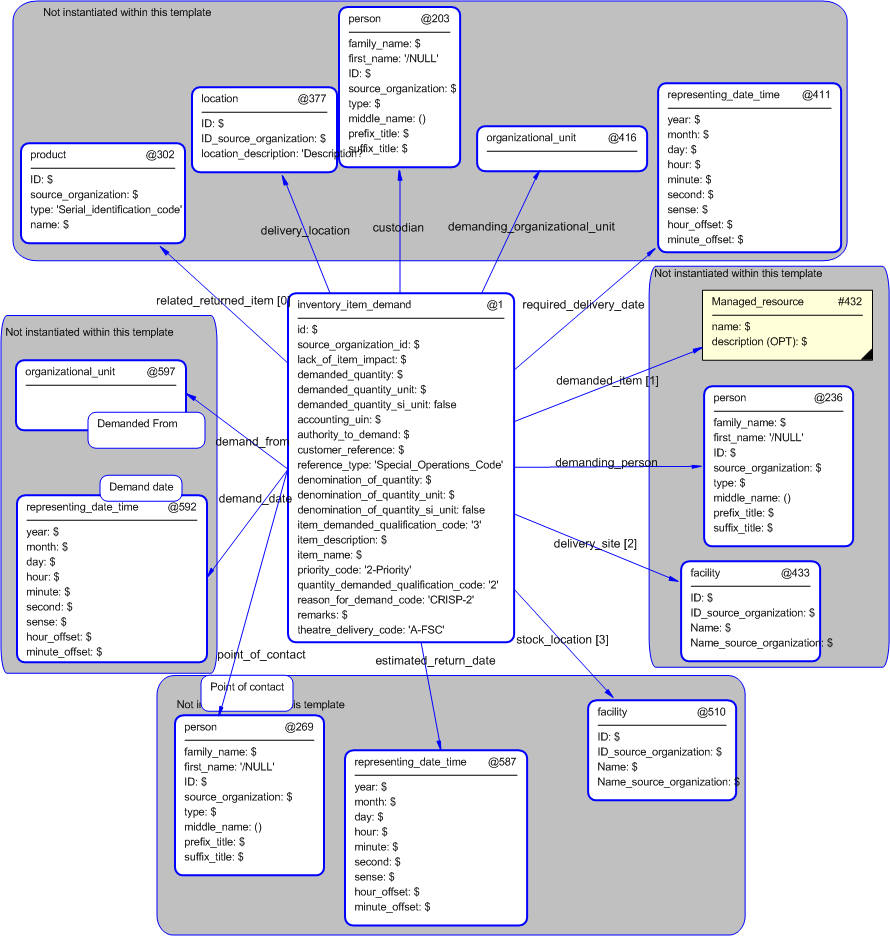

The EXPRESS-G diagram in

Figure

2

shows the templates and EXPRESS entities that are required

to represent the template

"inventory_item_demand".

The text highlighted in blue shows the template parameters.

Figure 2 — An EXPRESS-G representation of the Information model for inventory_item_demand

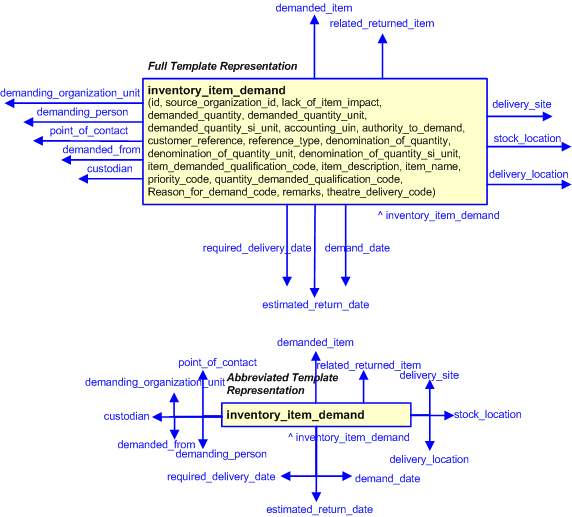

The graphic for the template to be used in other EXPRESS-G diagrams

is shown in Figure

3

below.

Figure 3 — The graphical representation of the inventory_item_demand template

The following input parameters are defined for this template:

The identifier assigned to a requirement.

This is the description of the impact of the resource demand not being met.

The organization or unit demanding the resource.

The person making the resource demand.

This is the date the resource demand is made.

The quantity of the demanded resource.

The units of measure for the quantity of the demanded resource.

The following classes and their sub-classes can be used:

Value should be set to true if the unit is a SI base unit defined by ISO, i.e.

kilogram (kg) for Mass,

second (s) for Time,

metre (m) for Displacement,

ampere (A) for Electrical current,

kelvin (K) for Temperature,

mole (mol) for Amount of substance, and

candela (cd) for Luminous intensity. If this is not the case it should be set to false.

Note that the representation of true and false depends on exchange format. In Part 11 (a STEP file) true is

represented by the string ".T.", and false by ".F.", while in Part 28 (XML) they are represented by text strings

"true"

and "false".

This is the identifier (UIN) of the inventory item demand.

This is the authority for the resource demand.

This is a reference to the custodian of the inventory item when delivered.

This is a reference number provided by the organization demanding the item.

reference_type (Default=Customer_reference_code,Type='CLASS', Optional)

This is the reference type used in conjunction with the customer reference.

This is a reference to the delivery facility or location.

This is a reference to a site within the demanding organization.

This is the identifier of the unit from which the item is demanded.

This is a reference to the specification of the item being demanded.

The quantity that represents a unit of purchase.

The required value assigned to a denomination.

The following classes and their sub-classes can be used:

Value should be set to true if the unit is a SI base unit defined by ISO, i.e.

kilogram (kg) for Mass,

second (s) for Time,

metre (m) for Displacement,

ampere (A) for Electrical current,

kelvin (K) for Temperature,

mole (mol) for Amount of substance, and

candela (cd) for Luminous intensity. If this is not the case it should be set to false.

Note that the representation of true and false depends on exchange format. In Part 11 (a STEP file) true is

represented by the string ".T.", and false by ".F.", while in Part 28 (XML) they are represented by text strings

"true"

and "false".

This is the date on which it is estimated that the demanded item will be returned to the issuer.

This is an item demand qualification code. The values are numerical codes ranging from 0 to 9.

This is the textual description of the demanded item. It may be used to describe the Item in the absence of an NSN.

Any details of item that will help in identifying it will be used, such as description and associated equipment type or Manufacturer’s

Part Number, known stockist, stockist’s address or other contact details, WESPIL No, BR 2525 Ref No (Part, Folio, and Index),

PIL or IPC (Alphanumeric of PIL/IPC also to be given). Manufacturer’s Part Number to be used if no other information available

or if it might help identification.

This is the name of the item demanded.

This is the point of contact for the demand.

priority_code (Default=Inventory_item_demand_priority_code,Type='CLASS')

This is the priority of the demand. See the Standard Priority Codes specified in JSP 886, Volume 3, Part 1, Section 2.

This is the quantity demanded qualification code of the demand. It allows or prevents reduced or staged quantities to be delivered.

This is a code to classifiy the reason for demand or justification.

This is the reference to the item that is being replaced by the item demanded.

This is for specifications of any special requirements, including packaging, handling, transportation etc..

This is the required delivery date for the demanded item.

This is a reference to the location (facility) where the stock will be held when delivered.

This is the theatre into which the demanded item is required to be delivered.

This is required so that supply chain pipeline times can be calculated for performance monitoring.

The following reference parameters are defined for this template:

%^target = $inventory_item_demand.inventory_item_demand%

The instantiation path shown below specifies the entities that are to be

instantiated by the template.

A description of templates and the syntax for the instantiation path is

provided in the

Templates Help/Information section.

/

resource_demand(

id=@id,

source_organization_id=@source_organization_id,

lack_of_item_impact=@lack_of_item_impact,

demanding_organization_unit=@demanding_organization_unit,

demanding_person=@demanding_person,

demand_date=@demand_date,

demanded_quantity=@demanded_quantity,

demanded_quantity_unit=@demanded_quantity_unit,

demanded_quantity_si_unit=@demanded_quantity_si_unit)/

%^ref_demand = $resource_demand.resource_demand%

-- create the inventory_item_demand Applied_activity_assignmentApplied_activity_assignment.role = '/IGNORE'

-- create the link to the ref resource demand Applied_activity_assignment.assigned_activity ->

^ref_demand

%^inventory_item_demand =

Applied_activity_assignment%

-- [Optional accounting_uin] /

identifier(

ID=@accounting_uin,

source_organization=@source_organization_id,

type='Unit_identification_number',

items=^inventory_item_demand)/

-- authority_to_demand /

assigning_descriptor(

descr=@authority_to_demand,

class_name='Authority_to_demand',

ecl_id='urn:plcs:rdl:uk_defence',

is_assigned_to=^inventory_item_demand)/

-- [Optional Custodian] (G.I. needs to know this is a new instance and not a reuse of the next one) Organization_or_person_in_organization_assignmentOrganization_or_person_in_organization_assignment.role = '/IGNORE'

Organization_or_person_in_organization_assignment.items ->

^inventory_item_demand

Organization_or_person_in_organization_assignment.assigned_entity ->

@custodian-- [Optional customer reference] /

identifier(

ID=@customer_reference,

source_organization=@source_organization_id,

type=@reference_type,

items=^inventory_item_demand)/

-- [Optional delivery_location] Location_assignmentLocation_assignment.role = '/IGNORE'

Location_assignment.location_for_assignment ->

@delivery_locationLocation_assignment.entity_for_location ->

^inventory_item_demand

-- Delivery_site

^inventory_item_demand.items ->

@delivery_site-- Demanded_from (G.I. needs to know this is a new instance and not a reuse of the next one) Organization_or_person_in_organization_assignmentOrganization_or_person_in_organization_assignment.role = '/IGNORE'

Organization_or_person_in_organization_assignment.items ->

^inventory_item_demand

Organization_or_person_in_organization_assignment.assigned_entity ->

@demanded_from-- create the link to the demanded item

^inventory_item_demand.items ->

@demanded_item-- Denomination_of_quantity /

assigning_resource_property(

property_class_name='Denomination_of_quantity',

property_ecl_id='urn:plcs:rdl:uk_defence',

described_element=^inventory_item_demand)/

%^denom_qty = $assigning_resource_property.property%

/

resource_property_numeric(

value=@denomination_of_quantity,

unit=@denomination_of_quantity_unit,

unit_ecl_id='urn:plcs:rdl:uk_defence',

si_unit=@denomination_of_quantity_si_unit,

context='Numerical_representation_context',

context_ecl_id='urn:plcs:rdl:uk_defence',

property=^denom_qty)/

-- [Optional Estimated_Return_date] Date_or_date_time_assignmentDate_or_date_time_assignment.role = '/IGNORE'

Date_or_date_time_assignment.items ->

^inventory_item_demand

Date_or_date_time_assignment.assigned_date ->

@estimated_return_date-- [Optional Item Demanded Qualification code] /

assigning_reference_data(

class_name=@item_demanded_qualification_code,

ecl_id='urn:plcs:rdl:UK_Defence',

items=^inventory_item_demand)/

-- item description /

assigning_descriptor(

descr=@item_description,

class_name='Description',

ecl_id='urn:plcs:rdl:uk_defence',

is_assigned_to=^inventory_item_demand)/

-- item name /

identifier(

ID=@item_name,

source_organization=@source_organization_id,

type='Name',

items=^inventory_item_demand)/

-- [Optional point_of_contact] (G.I. needs to know this is a new instance and not a reuse of a previous or subsequent one)

Organization_or_person_in_organization_assignmentOrganization_or_person_in_organization_assignment.role = '/IGNORE'

Organization_or_person_in_organization_assignment.items ->

^inventory_item_demand

Organization_or_person_in_organization_assignment.assigned_entity ->

@point_of_contact-- Priority code /

assigning_reference_data(

class_name=@priority_code,

ecl_id='urn:plcs:rdl:UK_Defence',

items=^inventory_item_demand)/

-- [Optional Quantity demanded qualification code] /

assigning_reference_data(

class_name=@quantity_demanded_qualification_code,

ecl_id='urn:plcs:rdl:UK_Defence',

items=^inventory_item_demand)/

-- reason_for_demand_code /

assigning_reference_data(

class_name=@reason_for_demand_code,

ecl_id='urn:plcs:rdl:UK_Defence',

items=^inventory_item_demand)/

-- [Optional Related returned item]

^inventory_item_demand.items ->

@related_returned_item-- [Optional Remarks] /

assigning_descriptor(

descr=@remarks,

class_name='Remarks',

ecl_id='urn:plcs:rdl:uk_defence',

is_assigned_to=^inventory_item_demand)/

-- Required_delivery_date Date_or_date_time_assignmentDate_or_date_time_assignment.role = '/IGNORE'

Date_or_date_time_assignment.items ->

^inventory_item_demand

Date_or_date_time_assignment.assigned_date ->

@required_delivery_date-- [Optional Stock Location]

^inventory_item_demand.items ->

@stock_location-- Theatre_delivery_code /

assigning_reference_data(

class_name=@theatre_delivery_code,

ecl_id='urn:plcs:rdl:UK_Defence',

items=^inventory_item_demand)/

The following entities are instantiated with attributes as specified:

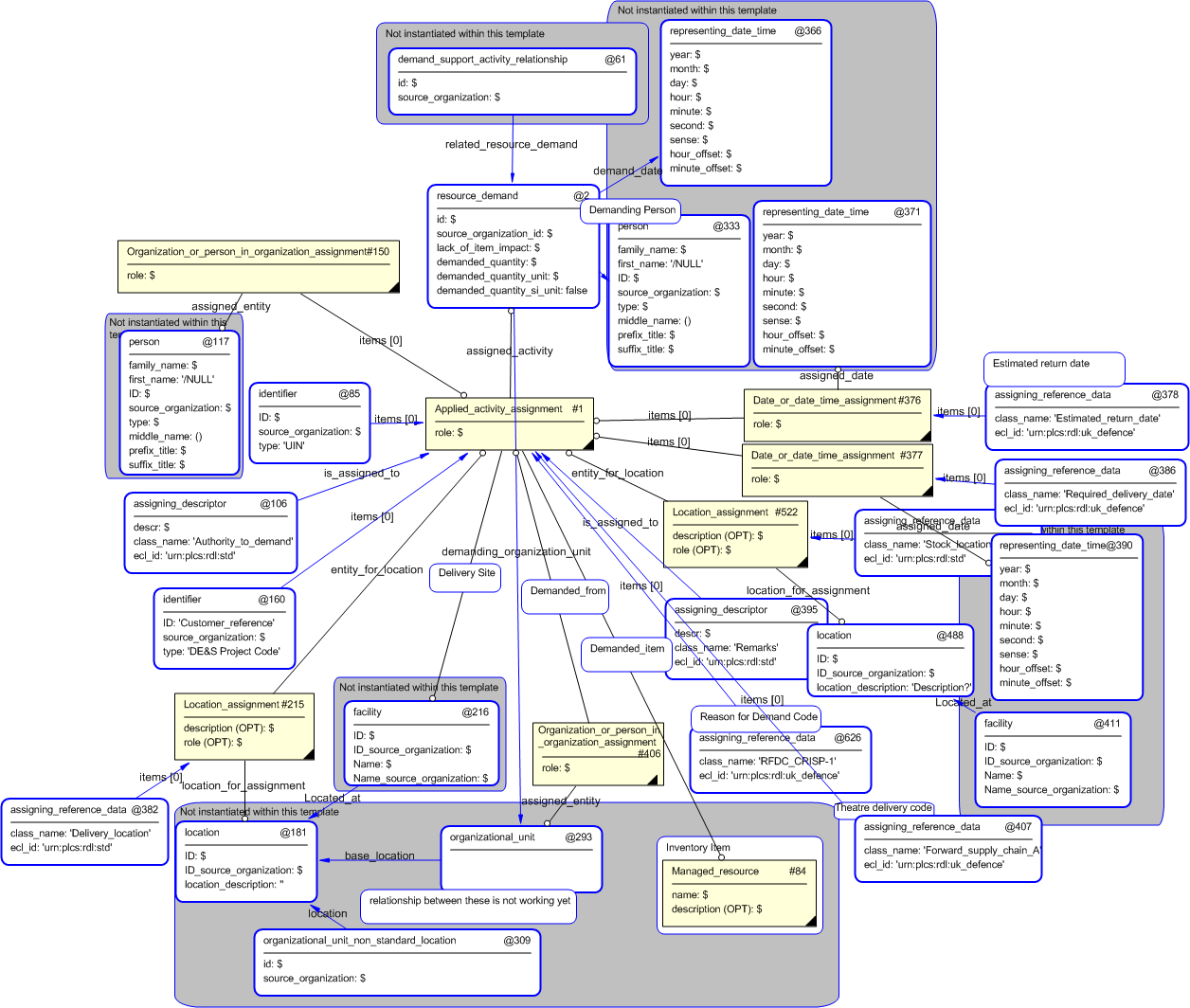

The instance diagram in Figure

4

shows an example of the EXPRESS entities and templates that are instantiated by the template:

/inventory_item_demand(id='''', source_organization_id='''', lack_of_item_impact='''', demanding_organization_unit='''', demanding_person='''', demand_date='''', demanded_quantity='''', demanded_quantity_unit='''', demanded_quantity_si_unit='''', accounting_uin='''', authority_to_demand='''', custodian='''', customer_reference='''', reference_type='''', delivery_location='''', delivery_site='''', demanded_from='''', denomination_of_quantity='''', denomination_of_quantity_unit='''', denomination_of_quantity_si_unit='''', estimated_return_date='''', item_demanded_qualification_code='''', item_description='''', item_name='''', point_of_contact='''', priority_code='''', quantity_demanded_qualification_code='''', reason_for_demand_code='''', related_returned_item='''', remarks='''', required_delivery_date='''', stock_location='''', theatre_delivery_code='''')/

(an illustration of the consolidated inventory_item_demand template is shown in

Figure

5 below.)

Figure 4 — Entities instantiated by inventory_item_demand template

The instance diagram in

Figure

5

shows the graphic symbol for the template that is to be

used in other instance diagrams. The example template is:

/inventory_item_demand(id='''', source_organization_id='''', lack_of_item_impact='''', demanding_organization_unit='''', demanding_person='''', demand_date='''', demanded_quantity='''', demanded_quantity_unit='''', demanded_quantity_si_unit='''', accounting_uin='''', authority_to_demand='''', custodian='''', customer_reference='''', reference_type='''', delivery_location='''', delivery_site='''', demanded_from='''', denomination_of_quantity='''', denomination_of_quantity_unit='''', denomination_of_quantity_si_unit='''', estimated_return_date='''', item_demanded_qualification_code='''', item_description='''', item_name='''', point_of_contact='''', priority_code='''', quantity_demanded_qualification_code='''', reason_for_demand_code='''', related_returned_item='''', remarks='''', required_delivery_date='''', stock_location='''', theatre_delivery_code='''')/

Figure 5 — Instantiation of inventory_item_demand template

Characterizations

No common characterizations of the template

inventory_item_demand

have been identified. However, the ISO 10303-239 EXPRESS model

may enable other assignments to the entities instantiated by the template.