| Business DEX (NDLO003):— Parts_and_Parts_Lists | Date: 2007/10/12 12:27:18 Revision: 1.18 |

Purpose

This NDLO-DEX shall exchange support data for a part and its constituent parts from the development stage through the retirement stage, as input to management processes, technical analyses and support.

Usage

This NDLO-DEX provides input data for risk and configuration management processes, and for all technical processes of the life cycle stages. Typical usage is to assess allocation of support requirements for product design, and the continuous review of recommendations for support tasks and resources. It enables identification of support significant parts for a parent part, specific to its use in a system.

This section provides an overview of the business DEXs.

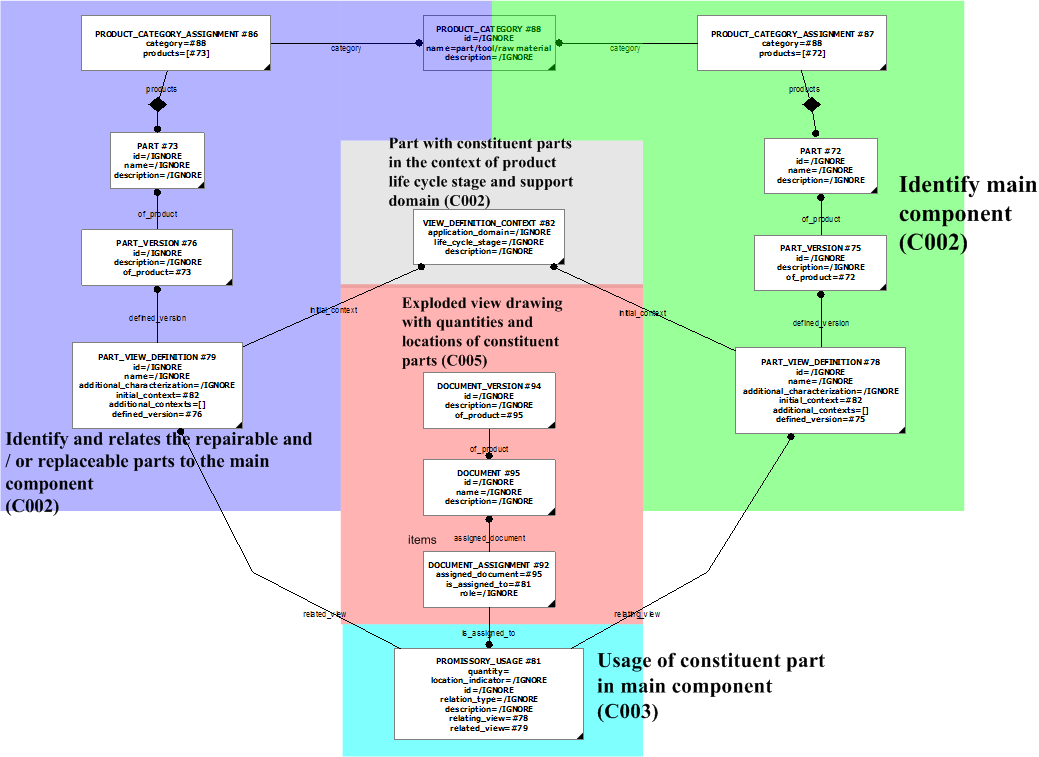

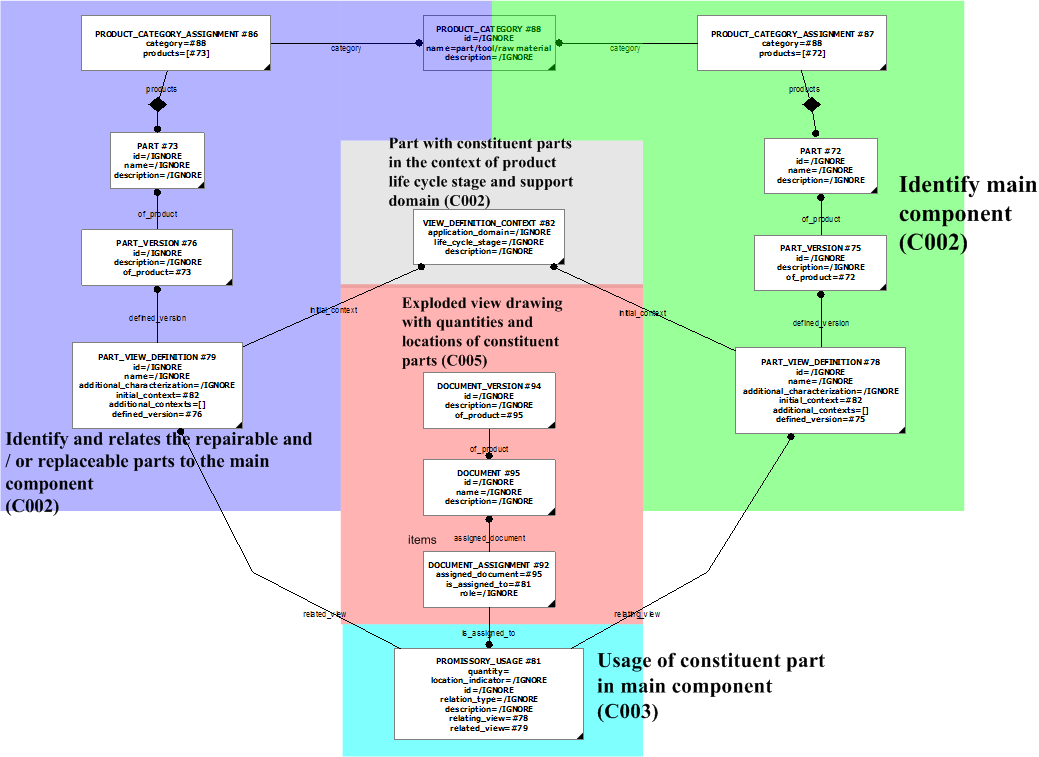

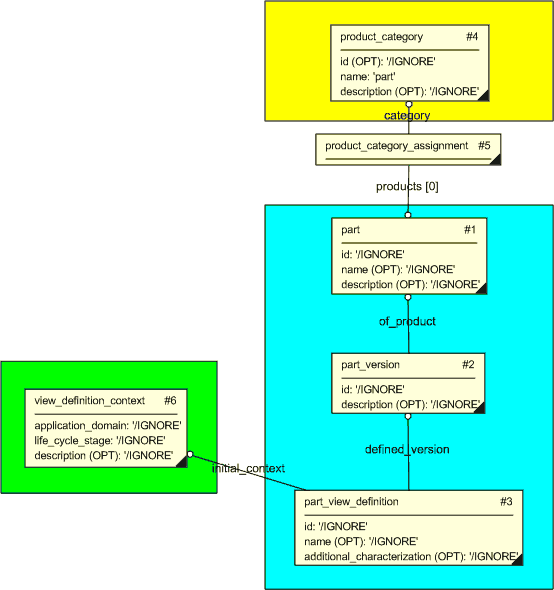

Parts and parts lists

The business DEX represents the main compenents as parts (green box). Integrated, repairable and maintainable parts to the main component are also modelled as parts (blue box). The context of the business DEX is support stage (grey box). The red box represents the documentation, e.g. view drawings with location and quantities of constituent parts.

Device tool supply item

The business DEX identifies supply items, represented as parts (blue box) necessary for the maintenance and operation of the device. The category of the device is included (yellow box) and the context is support stage (green box).

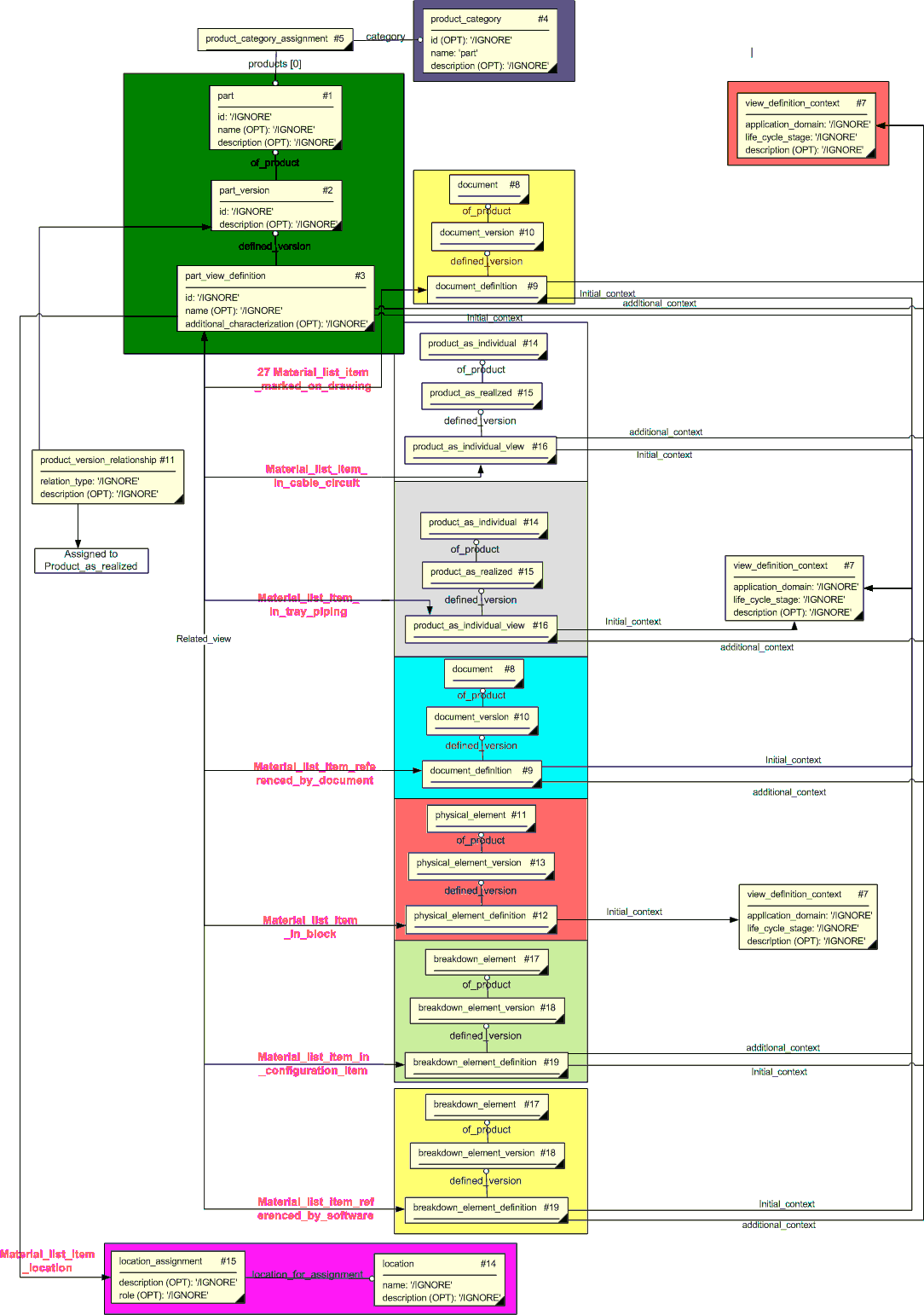

Usage of material list item

The business conept represents a material list item as a part (dark green box), attaches documentation that describes the material list item (yellow box), assigns a location code (pink box at the bottom). The context is support stage (red box at the top). A material list item can be of the following types:

|

Business function id |

Business function description |

Business constraints |

Parts and part lists |

Device tool supply item |

Usage of material list item |

|---|---|---|---|---|---|

| 1 | Relate the part to its model type, e.g. Ford Orion | There shall be zero or one instance for an instance of Step #7. | x | - | - |

| 2 | Relate the part to its brand name | There shall be zero or one instance for an instance of Step #7. | x | - | - |

| 3 | Assign supplier specific internal code type identifier | There shall be zero or one instance for an instance of Step #7. | x | - | - |

| 4 | Relate an identifier to the organization that assigned the identifier | The shall be one or more instances for one instance of an identifier. | - | - | - |

| 4.1 | Assign code type identifier to the organization that assigned the part identifier | There shall be zero or one instance of the class for an organization. Use class organization_identification_code when subtype is unknown. | - | - | - |

| 4.2 | Assign name to the organization that assigned the part identifier | There shall be one instance of the class if Step #4.1 has no instance, otherwise zero instance is permitted. | - | - | - |

| 5 | Assign code type identifier to the part version that is represented | There shall be one or more instances for one instance of Step #7. | x | x | x |

| 6.3 | Categorize a part as a maintenance object | NA | x | - | - |

| 6.4 | Categorize a part as a replaceable object | NA | x | - | - |

| 6.5 | Categorize a part as a repair part | NA | - | - | - |

| 6.6 | Categorize a part as a general support item | - | x | - | |

| 6.7 | Categorize a part as an item for requisition | - | - | - | |

| 7 | Assign manufacturer part number to the part | There shall be zero or one instance of the class for one instance of a Part. The superclass as well as siblings to the class are permitted to identify a part. There shall be one or more instances of an identifier for one instance of a Part. | x | x | - |

| 7.1 | Classificaiton of items as 'preferred' is removed from all DEXes | - | - | - | |

| 7.2 | NA (only in DEX003) | - | - | - | |

| 7.3 | Provide identifier to a part that only is identified by its APL identifier | This instance applies only as alias to OEM part type code when Step #7 has no value | x | - | - |

| 8 | Assign a unique manufacturer name to the part | - | - | - | |

| 9 | Identify product category for the part | - | - | - | |

| 9.1 | Add code type identifier for part category | A >part<shall have one instance. There shall be one or more instances of >part< for one instance. | - | x | - |

| 9.2 | Identify the part category by its name | The entity type instance is the same as in Step #9.1. A >part<shall have one instance. There shall be one or more instances of >part< for one instance. | - | - | - |

| 10 | Assign an identifier to the support view of the maintainable part at its intended usage | There shall be no more than one instance of the identifier for one Part_view_definition instance. | - | - | - |

| 10.1 | Assign the Allowance Parts List identifier that applies to the support view of the maintainable configuration item at its intended usage | There shall be no more than one instance of the identifier for one Part_view_definition instance. | x | - | - |

| 10.2 | Assign the Allowance Parts List identifier that applies to the support view of the support material | There shall be no more than one instance of the identifier for one Part_view_definition instance. | - | x | - |

| 11 | Identify the Parts List for the parent part | This is the same instance as Steps #10, 10.1 or 10.2 as applicable. | - | - | - |

| 12 | Identify the constituent parts (parts list members) to the parent part | There shall be zero, one or more instances for one instance of Step #11. | - | - | - |

| 12.1 | Define parts to be members of an Allowance Parts List | NA | - | - | - |

| 12.2 | Define parts to be members of a Parts List | There shall be one or more instances for one instance of Step #10, 10.1 or 10.2 as applicable. | x | - | - |

| 13 | Assign description of the Allowance Parts List code | There shall be one instance for one instance of Step #10.1. | x | - | - |

| 13.1 | Removed | NA | - | - | - |

| 13.2 | Assign description of the Parts List code | There shall be one instance for one instance of Step #10. | - | - | - |

| 14 | Assign a revision mark to the data record for constituent parts in parent part usage | One or more class instances may apply to an entity type instance. | x | - | - |

| 15 | Assign a document applicable to the parent and its constituent parts | There shall be zero, one or more instances for one instance of Step #12. There shall be one or more instances for an instance of Step #15.1. There shall be one instance for an instance of Step #16 or 17. | x | - | - |

| 15.1 | Identify the document | There shall be zero or one instance for one instance of Step #15. | x | - | - |

| 15.2 | Identify document version number | NA | x | - | - |

| 16 | Identify constituent part position number on drawing | There shall be zero or one instance for one instance of Step #11. There shall be one instance if Step #17 has no instance value. | x | - | - |

| 17 | Identify symbol (e.g. circuit) used to represent the constituent part on the drawing | There shall be zero or one instance for one instance of Step #11. There shall be one instance if Step #16 has no instance value. | x | - | - |

| 18 | Identify quantity of identical constituent parts per position number on drawing | There shall be one instance for one instance of Step #15. | x | - | - |

| 19 | Define unit of measure for a quantity | NA | - | - | - |

| 19.1 | Classify the representation of the quantity value | NA | - | - | - |

| 19.2 | Classify the context for the numerical representation | NA | - | - | - |

| 20 | Identify quantity of identical constituent parts in the parent part | There shall be one instance for one instance of Step #11 when the data are related to an instance of Step #11. | x | - | - |

| 20.1 | Identify partial quantity of identical parts in a parent part, related to individual identifiers on a drawing | There shall be one instance for one instance of Step #15 when the data given are related to an instance of Step #16 or 17. This step applies as an alternative to step #20 when it is uncertain that this quantity represents the total consolidated quantity. Use, to be declared in the exchange agreement. | x | - | - |

| 21 | Identify a document that holds a Material list for a part | There shall be at least one class instance for one instance of the Material list item identifier (Step #28) | - | - | x |

| 21.1 | Assign revision number to Material list | Only one class instance shall apply to one entity type instance. | - | - | x |

| 21.2 | Define the Material list document | There shall be one instance of the class per Step #28. | - | - | x |

| 22 | Identify sequential number for item in Material List | There shall be at least one istance of the class for one instance of the Material List | - | - | - |

| 23 | Identify item mark on the drawing when the Material list is part of a drawing | NA | - | - | - |

| 24 | Identify quantity of Material list items per item mark on drawing | - | - | - | |

| 25 | Identify code for unit of issue for purchase of Material list item shown on the drawing | There shall be one instance for one instance of Step #24. | - | - | - |

| 25.1 | Describe unit of issue for purchase of Material list item shown on the drawing | There shall be one instance for one instance of Step #24. | - | - | - |

| 26 | Identify number of appearances of the item mark on the drawing holding the Material list | There shall be only one instance of the class for a Material list item instance. | - | - | - |

| 27 | Relate the Material list to its member parts | One or more instances of Promissory_usage apply to one instance of Step #28. One or more instances apply to one instance of Step #21.2. | - | - | x |

| 28 | Identify Material list item by its list item identifier | - | - | x | |

| 28.1 | Identify Material list item by its acquisition part identifier | - | - | x | |

| 28.2 | Identify Material list item by its subordinate identifier needed for construction | - | - | x | |

| 28.3 | Identify context for the Material list item | - | - | - | |

| 28.4 | Categorize a part as a Material list item | - | - | - | |

| 29 | Identify the life cycle stage for which the data are valid | - | - | - | |

| 29.1 | Classify 'Support_stage' as a life cycle stage | x | x | x | |

| 29.2 | Classify 'Production_stage' as a life cycle stage | - | - | x | |

| 30 | Identify the application domain for which the data are valid | - | - | - | |

| 30.1 | Classify 'Product_life_cycle_support' as an application domain | x | x | x | |

| 30.2 | Classify 'Manufacturing_processes' as an application domain | - | - | x | |

| 31 | Assign support material identifier code to the part | One instance shall have 0, one or more different value instances of Step #32. There is one instance of Step #6.6 for each unique combination of instances in Steps #31 and 32. | - | x | - |

| 32 | Identify alternative support material delivery opportunities | An instance is unique for one instance of Step #31 where an unset value is permitted as one instance. | - | x | - |

| 33 | Identify a part with its nomenclature (e.g. 'adapter, socket wrench') | - | x | - | |

| 34 | Identify a part with its name (e.g. ''1/2'' to 3/8'', sq drive') | - | x | - | |

| 35 | Identify a part as a POL (Petroleum/Oil/Lubricant) product | - | x | - | |

| 36 | Identify the part with its NATO COG | - | x | - | |

| 37 | Add code type identifier when part is a test equipment | A >part<may have zero or one instance. There shall be one or more instances of >part<for one instance. | - | x | - |

| 37.1 | Identify the Test Equipment type by its name | The entity type instance is the same as in Step #37. A >part< may have zero or one instance. There shall be one or more instances of >part<for one instance. | - | - | - |

| 38 | Add a note code with specific information about the support material item | There shall be one instance per instance of Step #31 and 32 combined. | - | x | - |

| 38.1 | Identify the specific material information note | - | - | - | |

| 38.2 | The specific material information note | - | - | - | |

| 39 | Provide additional information pertaining to the support material item | - | x | - | |

| 39.1 | Classify the representation context for description of support material | - | - | - | |

| 40 | Identify the hazard material user group code of the support material | A >part< shall have one instance. There shall be one or more instances of >part< for one instance. | - | x | - |

| 40.1 | Identify the hazard group of the part | The entity type instance is the same as in Step #40. A >part<may have zero or one instance. There shall be one or more instances of >part< for one instance. | - | - | - |

| 41 | Identify support material disposal method | - | x | - | |

| 41.1 | Identify support material disposal method | - | - | - | |

| 41.2 | Characterize the support material according to its disposal method | - | - | - | |

| 41.3 | Assign a Encoding system document to the name of the assigned property | There shall be zero or one instance for one instance of #41 | - | - | - |

| 41.4 | Identify the document version number | - | - | - | |

| 41.5 | Identify document number | - | - | - | |

| 41.6 | Assign classification to the Document | There shall only be one instance for one instance of Step #41.3 | - | - | - |

| 42 | Reference the standard the support material is based upon | - | - | - | |

| 43 | Assign a document representing the standard for the support material | - | x | - | |

| 44 | NA (only in DEX003) | - | - | - | |

| 44.1 | NA (only in DEX003) | - | - | - | |

| 45 | Characterize the essentiality of the part as used in its parent part | There shall be one instance of this Step per instance of Step #12. | x | - | - |

| 45.1 | Assign essentiality code to the part | There shall be one instance for an instance of 45.2. | - | - | - |

| 45.2 | Assign name of the essentiality of the part | There shall be zero or one instance for an instance of 45. | - | - | - |

| 45.3 | Assign a Encoding system document to the name of the assigned property | There shall be zero or one instance for one instance of #41 | - | - | - |

| 45.4 | Identify the document version number | - | - | - | |

| 45.5 | Identify document number | There shall only be one instance for one instance of Step #41.3 | - | - | - |

| 45.6 | Assign classification to the Document | There shall only be one instance for one instance of Step #41.3 | - | - | - |

| 46 | Assign a document to a defined view of the part | There shall be zero, one or more instances for one instance of Step #10. | - | - | - |

| 47 | Identify document version number | NA | - | - | - |

| 48 | Identify a document that applies to a defined view of a part | NA | - | - | - |

| 49 | Identify the minimum level for a workshop authorized to replace this specific part in its actual usage | There shall be zero or one instance for an instance of Step #15. | x | - | - |

| 50 | Relate a maintenance level to a corresponding maintenance organization | There shall be zero or one instance for an instance of Step #49. | x | - | - |

| 51 | Define the maintenance level required to replace a part | NA | - | - | - |

| 52 | Provide identifier to a part that does not have a PN. | NA | - | x | - |

Business rules for 'Parts lists'

Compliance rules for 'Parts lists'

Business rules for 'Support Material Items'

Compliance rules for 'Support Material Items'

Business rules for 'Material list'

Compliance rules for 'Material list'

© OASIS 2010 — All rights reserved