| DEX: (D005) maintenance_plan — Maintenance plan | Date: 2007/09/14 16:11:29 Revision: 1.34 |

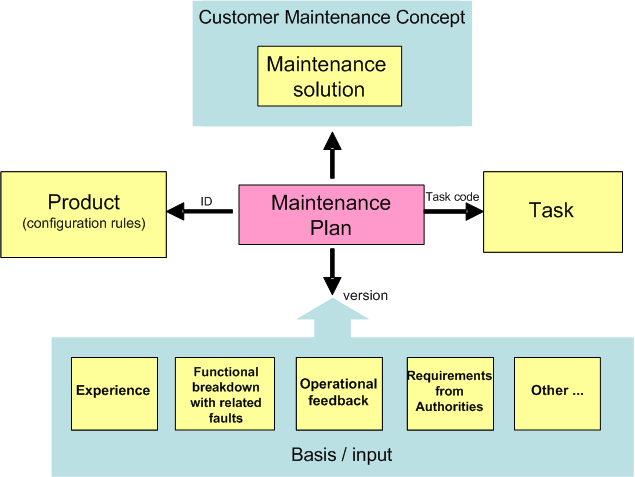

This DEX enables the transmission of maintenance tasks which are to be performed on a product in order to sustain the required function of the product, together with the conditions under which these maintenance tasks fall due.

The plan is prepared and established based on a Logistic Support Analysis, LSA, including:

The maintenance plan will provide input to maintenance scheduling activities (see DEX work_package_definition).

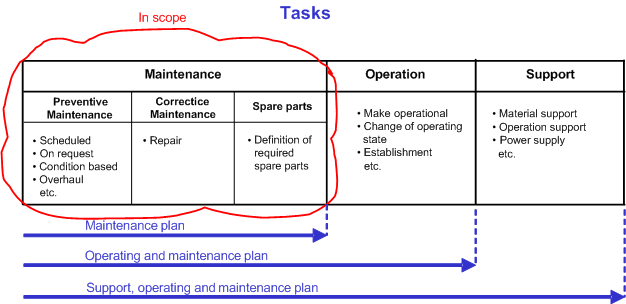

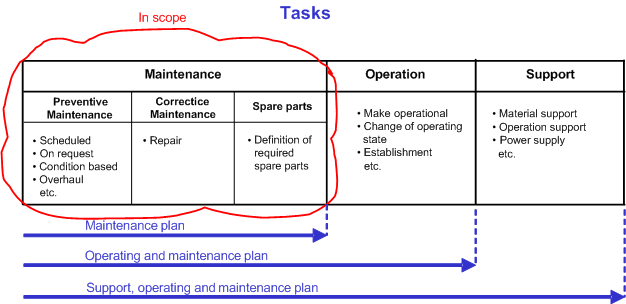

The types of tasks that is within the scope of maintenance plan is visualized in figure 2.

A maintenance plan may include sub plans covering relevant sub-divisions of the product or deployment environemt.

Maintenance plans provide the basis for planning, budgeting, preparing, performing and assessing current maintenance of a product and its included parts.

Maintenance plans may be produced by manufacturers, suppliers, procurement authorities, users and others.

This exchange enables the transmission of the data exchange set (DEX) Maintenance Plan.

A maintenance plan is initially prepared during the latter stages of the detail design and development phases and is continuously assessed and adjusted throughout the lifetime of a system or product. The plan is prepared and established based on a Logistic Support Analysis, LSA, including:

The purpose of a maintenance plan is to specify maintenance tasks necessary to sustain the requirements of use, reliability performance, safety and economy throughout its lifetime.

A maintenance plan contains information on:

General administrative data includes identification of an individual revision of the maintenance plan, involved parties, status, and date of issue.

The context information identifies the top item product to which the maintenance plan relates, the maintenance concept being applied, the support requirements which the plan adresses, and the deployment environment to which the plan applies, including the assumed operational use and resource availability.

The product information identifies and classifies each element in the breakdown of the product (system, functional, assembly etc) to which maintenance tasks applies.

The main purpose of the maintenance plan is to identify the maintenance tasks that applies to each element in the products breakdown structure. For each specified task it also specifies who will perform the task, where it will be performed, the condition under which the task falls due, and how the task is to be performed.

A maintenance plan may include sub plans covering relevant sub-divisions of the product or deployment environment.

Maintenance plans provide the basis for planning, budgeting, preparing, performing and assessing current maintenance of a product and its included parts.

Maintenance plans may be produced by manufacturers, suppliers, procurement authorities, users and others.

© OASIS 2010 — All rights reserved