| Business DEX (NDLO004):— Parts_supply_data | Date: 2007/10/12 12:27:18 Revision: 1.19 |

Purpose

This NDLO-DEX shall exchange provisioning data about resource items from the development stage through the retirement stage, as input to management processes, technical analyses and support.

Usage

This NDLO-DEX provides input data for budget and planning of supply processes through the life cycle stages. Typical usage is to determine preferred source and best timing for supply activities.

This section presents an overview of the different business DEX.

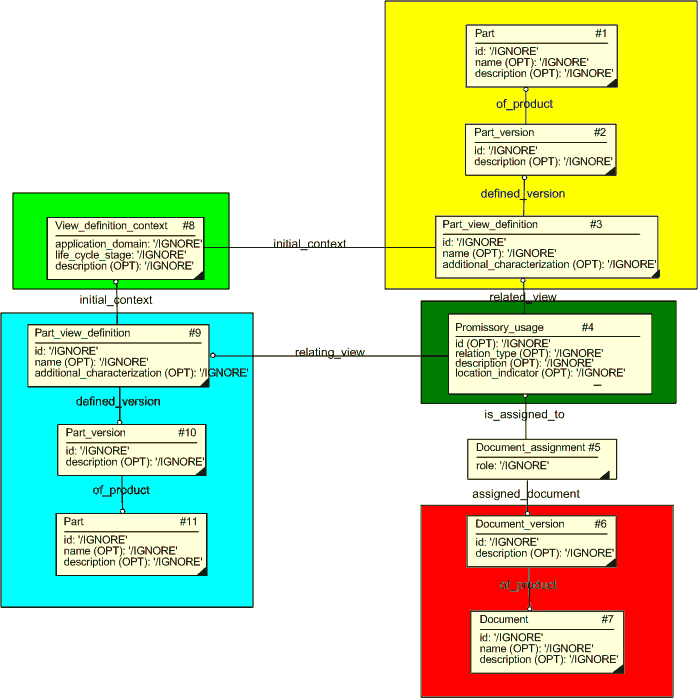

Part usage

The business DEX relates replaceable parts (yellow box) with constitutent maintainable parts (blue box)

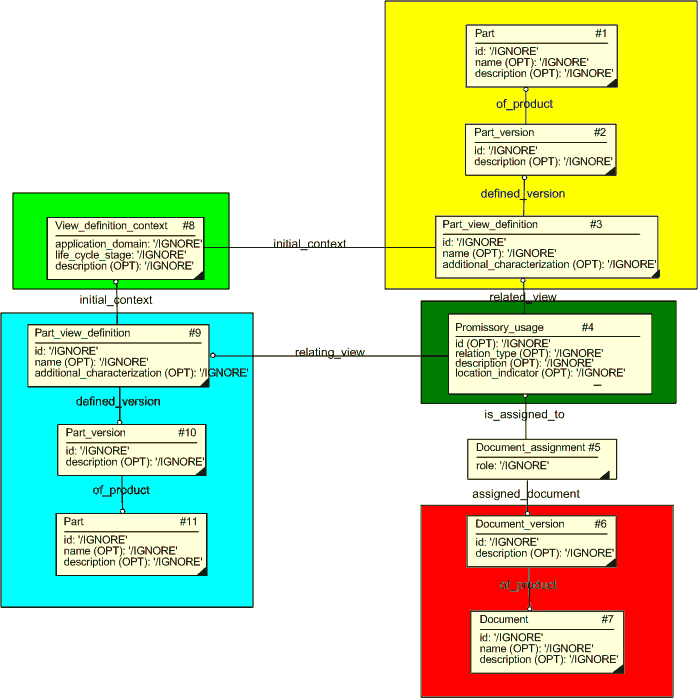

Part as resource

The business DEX defines the spare parts which are kept locally or centrally. Spare parts can refer to a ship or a fleet. It also includes information about the minimum authorization level required in order to use an organization as a supplier for a resource item. ????

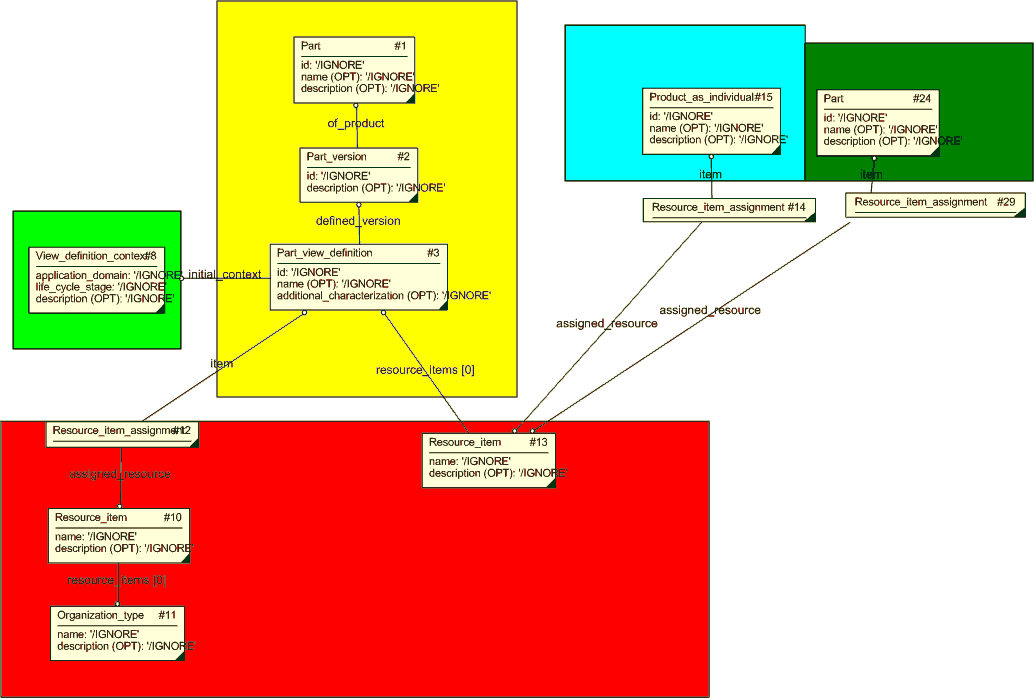

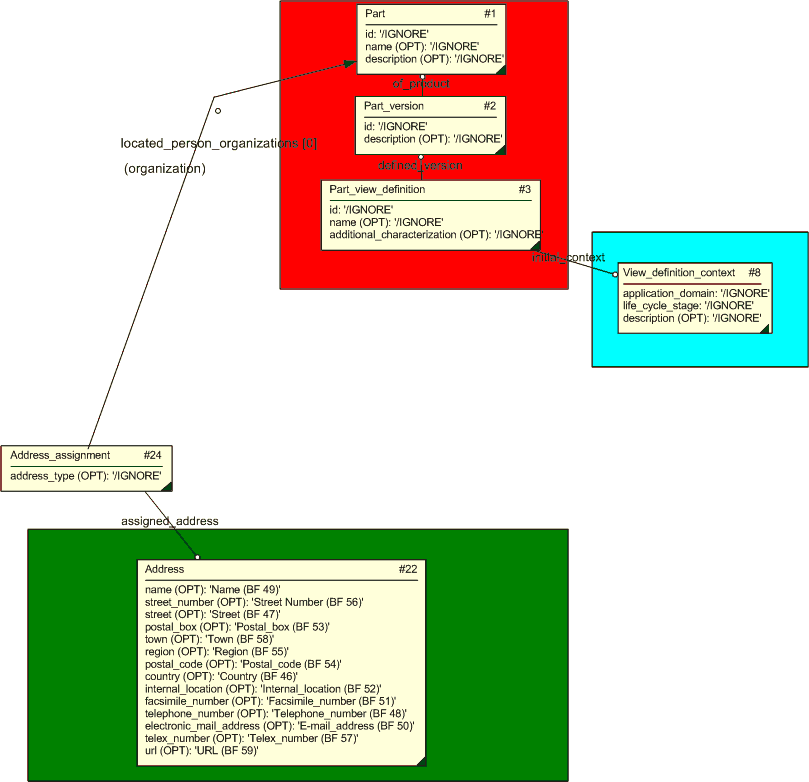

Part provisioning

The business DEX defines a number of significant data elements about the supplier of spare parts (red box) attached as attributes to a part. The green box shows the kind of data elements (name of the supplier, contact details as listed). The business DEX is used in the context of support.

The following business functions are defined:

The NDLO-DEX is divided into several supporting business functions (sometimes also referred to as steps). The table below indicates which functions are available for the various business DEXs. An "x" in the table indicates that the business function is available for a business DEX.

| Business function id | Business function | Business constraints | Part usage | Part as resource | Part provisioning | ||

| 1 | Identify the life cycle stage for which the data are valid | There shall be no more than one class instance for one instance of Part_view_definition. | x | x | x | ||

| 2 | Identify the application domain for which the data are valid | There shall be no more than one class instance for one instance of Part_view_definition. | x | x | x | ||

| 3 | Identify a maintenance object that requires spare parts by its Allowance Parts List identifier | There shall be one instance of the identifier for one Part_view_definition instance. | x | - | - | ||

| 3.1 | Identify the individual parent product that the resource item apply to | NA | - | x | - | ||

| 3.2 | Identify the fleet that the resource item apply to | NA | - | x | - | ||

| 3.3 | Assign manufacturer part number to the maintainable part that the spare part relates to | There shall be one instance for one instance of Stap #3. One instance may have more than one instance of Step #4.1. | x | x | x | ||

| 4 | Assign manufacturer part number to the spare part/device/tool/support item | There shall be one instance of the class for one instance of a Part. | x | x | x | ||

| 4.1 | Assign version identifier to the part | An instance shall have one or more instances of Step #3.3 or of Step #5 as applicable. | x | x | - | ||

| 5 | Categorize a part as a spare part | There shall be one instance for one instance of Step #4. | x | - | - | ||

| 5.1 | Categorize a part as a replaceable part | There shall be one instance for one instance of Step #4. | x | - | - | ||

| 5.2 | Categorize a part as a maintainable part | There shall be one instance for one instance of Step #3. | x | - | - | ||

| 6 | Relate an identifier to the organization that assigned the identifier | The shall be one or more instances for an identifier instance. The concatenated value of the identifier and Step #6.1 'exchange_data' shall be globally unque. | - | - | x | ||

| 6.1 | Assign code type identifier to the organization that assigned the part identifier | NA | - | - | x | ||

| 6.2 | Assign name to the organization that assigned the part identifier | There shall be one instance of the class if Step #6.1 has no instance, otherwise zero instance is permitted. | - | - | x | ||

| 7 | Assign NATO Stock Number (NSN) to part | There shall be one instance of the class for one instance of Step #4. | - | x | - | ||

| 7.1 | Identify repair parts as resource items | NA | - | - | - | ||

| 8 | NB: Dette steget i DEX006 implementeres ikke i første release til NDLO. En issue reises for å legge den inn senere. Identify recommended source for spare part | NA | - | x | - | ||

| 9 | Identify main contractor auxilliary part number for resource item | There shall be zero or one instance per instance of Step #4. | - | - | x | ||

| 10 | Define parts to be members of a Parts List | For an instance of Step #3, there shall be one class instance for each instance of Step #5.1. | x | - | - | ||

| 11 | Assign a drawing that displays a parent part and its constituent parts | There shall be one instance for each value combination of Steps #12, 14 and 15. | x | - | - | ||

| 12 | Provide identifier to a document | There shall be one identifier for one main entity instance. There shall be an instance for an instance of Step #4. | x | - | - | ||

| 13 | Identify document version number | NA | x | - | - | ||

| 14 | Identify constituent part position number on drawing | There shall be zero or one instance for one instance of Step #11. There shall be one instance if Step #15 has no instance value. | x | - | - | ||

| 15 | Identify symbol (e.g. circuit) used to represent the constituent part on the drawing | There shall be zero or one instance for one instance of Step #11. There shall be one instance if Step #14 has no instance value. | x | - | - | ||

| 16 | Relate resource item to the organization level permitted to use the resource item | There shall be one instance for each instance of Step #5. | - | x | - | ||

| 16.1 | Relate spare part resource item to the fleet of products to which it applies | For each instance of Step #7, there shall be one instance for each instance of Step #3.2. | - | - | - | ||

| 16.2 | Relate spare part resource item to the individual parent product to which it applies | For each instance of Step #7, there shall be one instances for each instance of Step #3.1. | - | x | - | ||

| 17 | Identify the minimum level for a workshop authorized to use the resource item | There shall be zero or one instance for one instance of Step #16. | - | x | - | ||

| 18 | Identify minimum replacement quantity of a resource item in its usage, e.g. litres of oil (in parent part, task independent) | There shall be zero or one instance per instance of Step #11. | x | - | - | ||

| 18.1 | Determine that a quantified value is calculated | NA | - | - | - | ||

| 18.2 | Identify contractor as context for a numerical value | NA | x | - | - | ||

| 18.3 | Identify contractor as context for a string representation item | NA | - | - | x | ||

| 18.4 | Classify the quantified value as provided by the parent part supplier | NA | - | - | - | ||

| 19 | Identify unit of delivery for resource item | There shall be one instance of 'exchange_data' for an instance of Step #18. Use the AP239 entity type that applies to the unit type, instead of Unit, for exchange of the unit code. | - | - | - | ||

| 20 | Provide description/name of unit_of_delivery_code | The entity instance is the same as in Step #19. There shall be one instance of 'exchange_data' for one instance of Step #19. | x | - | - | ||

| 21 | Identify recommended replacement frequency (Technical Replacement Factor) for a part in parent part usage | There shall be zero or one instance for an instance of Step #11. | x | - | - | ||

| 22 | Identify unit of measure for replacement frequency | NA | x | - | - | ||

| 23 | Identify recommended on board storage quantity for a part in its parent part usage | There shall be one instance per instance of Steps #3 and 10. | x | - | - | ||

| 24 | Define unit of measure for a quantity | NA | x | - | - | ||

| 25 | Identify recommended on shore storage quantity for a part in its parent part usage | There shall be one instance per instance of Steps #3 and 10. | x | - | - | ||

| 26 | Provide justification for an on board storage quantity recommendation | NA | x | - | - | ||

| 26.1 | Provide justification for an on shore storage quantity recommendation | NA | x | - | - | ||

| 27 | Identify analysis method used to recommend on board storage quantity for a part in its parent part usage | There shall be one instance for an instance of Step #23. | x | - | - | ||

| 28 | Identify analysis method used to recommend on shore storage quantity for a part in its parent part usage | There shall be one instance for an instance of Step #25. | x | - | - | ||

| 29 | Relate recommended storage quantity for a spare part held locally to the individual parent product that it supports | There shall be one instance per instance of Step #7 in the context of Step #3.1. | - | x | - | ||

| 30 | Relate recommended storage quantity for a spare part held centrally to the individual parent product that it supports | There shall be one instance per instance of Step #7 in the context of Step #3.1. | - | x | - | ||

| 31 | Relate recommended storage quantity for a spare part held centrally, to the fleet of products that it supports | There shall be one instance per instance of Step #7 in the context of Step #3.2. | - | x | - | ||

| 32 | Identify recommended consolidated quantity of spare parts to be held locally on an individual parent product | NA | - | x | - | ||

| 33 | Identify recommended consolidated quantity of spare parts to be held centrally to support an individual parent product | NA | - | x | - | ||

| 34 | Identify recommended consolidated quantity of spare parts to be held centrally to support a defined fleet of parent products | NA | - | x | - | ||

| 35 | Identify net catalogue price of spare part at time of main product production | There shall be one instance for an instance of Step #10. | x | - | - | ||

| 36 | Identify currency code for spare part price | There shall be one instance for an instance of Step #35. | - | - | x | ||

| 37 | Provide description for monetary code | There shall be one instance for an instance of Step #36. | - | - | x | ||

| 38 | Provide value for production lead time for delivery of part | There shall be one instance of this Step for an instance of Step #5. | - | - | x | ||

| 38.1 | Provide value for production lead time for delivery of part | There shall be one instance of this Step or of Step #38.2 for an instance of Step #38. | - | - | x | ||

| 38.2 | Provide a code to identify production lead time for delivery of part | There shall be one instance of this Step or of Step #38.1 for an instance of Step #38. | - | - | x | ||

| 38.3 | Define the code value used to identify production lead time for a part | There shall be one instance for an instance of Step 38.2. | - | - | - | ||

| 38.4 | Assign a Encoding system document to the name of the assigned property | There shall be zero or one instance for one instance of C152 | - | - | - | ||

| 38.5 | Identify the document version number | - | - | - | |||

| 38.6 | Identify the document that describes the encoding system | NA | - | - | - | ||

| 38.7 | Identify document number | NA | - | - | - | ||

| 39 | Determine that the property is represented as a code value | NA | - | - | x | ||

| 39.1 | Identify time unit as a measure of days | NA | - | - | x | ||

| 39.2 | Identify time unit as a measure of years | NA | - | - | x | ||

| 39.3 | Identify that a measure value was derived by assessment | NA | - | - | x | ||

| 40 | Provide shelf life limitation for spare part as a period of time | There shall be one instance of this Step for an instance of Step #5. | - | - | x | ||

| 40.1 | Provide shelf life limitation for spare part as a period of time | There shall be one instance of this Step or of Step #40.2 for an instance of Step #40. | - | - | x | ||

| 40.2 | Provide a code to identify shelf life for a part | There shall be one instance of this Step or of Step #40.1 for an instance of Step #40. | - | - | x | ||

| 40.3 | Define the code value used to identify shelf life time for a part | There shall be one instance for an instance of Step 40.2. | - | - | - | ||

| 41 | Describe a spare part | There shall be one instance for an instance of Step #41. | - | - | x | ||

| 42 | Relate descriptive information to a spare part | NA | - | - | x | ||

| 43 | Identify if spare part is repairable | There shall be one instance for an instance of Step #5. | - | - | x | ||

| 43.1 | Code identifying the spare part repairability | There shall be one instance for an instance of Step #43.2. | - | - | - | ||

| 43.2 | Name identifying the spare part repairability | There shall be one instance for an instance of Step #43. | - | - | - | ||

| 44 | Provide contractor recommended source for spare part | There shall be one instance for an instance of Step #5. | - | - | x | ||

| 44.1 | Provide a code to identify main contractor recommended source of spare part | There shall be one instance of this for one instance of Step #44. | - | - | - | ||

| 44.2 | Provide a name to identify main contractor recommended source of spare part | There can be one instance of this for one instance of Step #44. | - | - | - | ||

| 45 | Provide contact details for part supplier | There shall be one instance for an instance of Step #6.1 unless otherwise specified in an Exchange Agreement. | - | - | x | ||

| 46 | Provide country code of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 47 | Provide street address of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 48 | Provide supplier telephone number | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 49 | Provide commercial name of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 50 | Provide e-mail address of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 51 | Provide facsimile number of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 52 | Provide internal location address for mail deliveries at supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 53 | Provide postal box of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 54 | Provide postal code of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 55 | Provide name of region for supplier address | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 56 | Provide street number for supplier address | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 57 | Provide telex number of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 58 | Provide name of town or city for supplier address | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x | ||

| 59 | Provide URL of supplier | There shall be zero or one instance per instance of Step #6.1 in the context of Step #4. | - | - | x |

© OASIS 2010 — All rights reserved