| Business DEX (NDLO001):— part_characterization | Date: 2007/10/12 12:27:18 Revision: 1.25 |

Purpose

This NDLO-DEX shall exchange design data chategorizing a part and material items from the development stage through the support stage, as input to management processes, technical analyses and support.

Usage

The NDLO-DEX provides input data for risk and configuration management processes, and for all technical processes of the life cycle stages. Typical usage is to assess allocation of support requirements for product design, and the continuous review of recommendations for support tasks and resources.

This section provides an overview of the business DEXs.

Characterize material list item

A material list item is a part used during the manufacturing process of the product, e.g. a steel plate used for the construction of the hull is a material list item. It is represented as a part in the PLCS model (blue box).

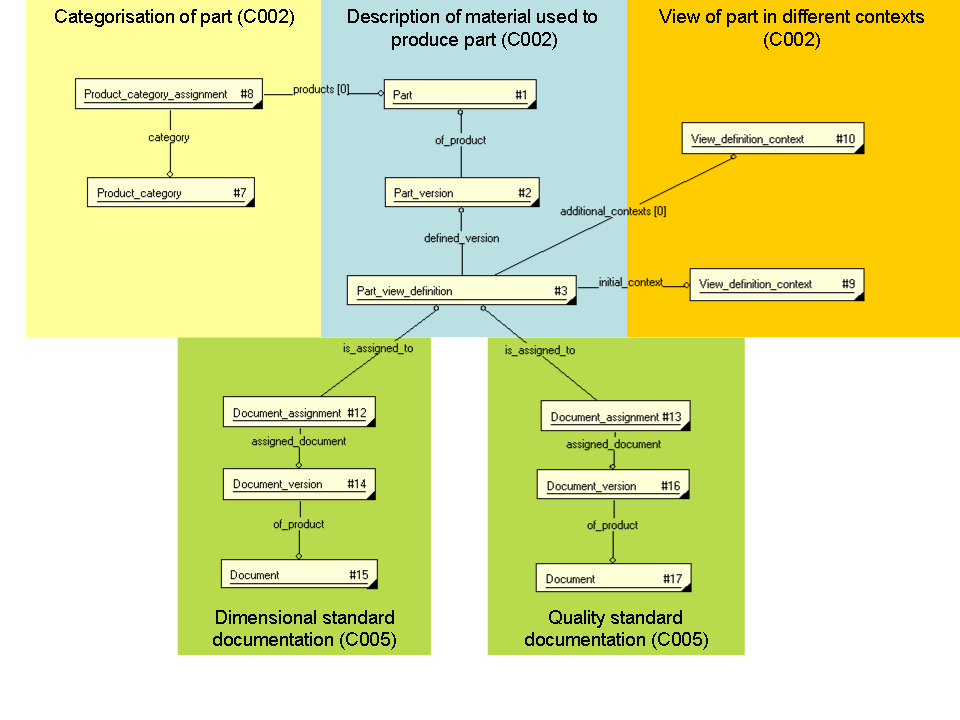

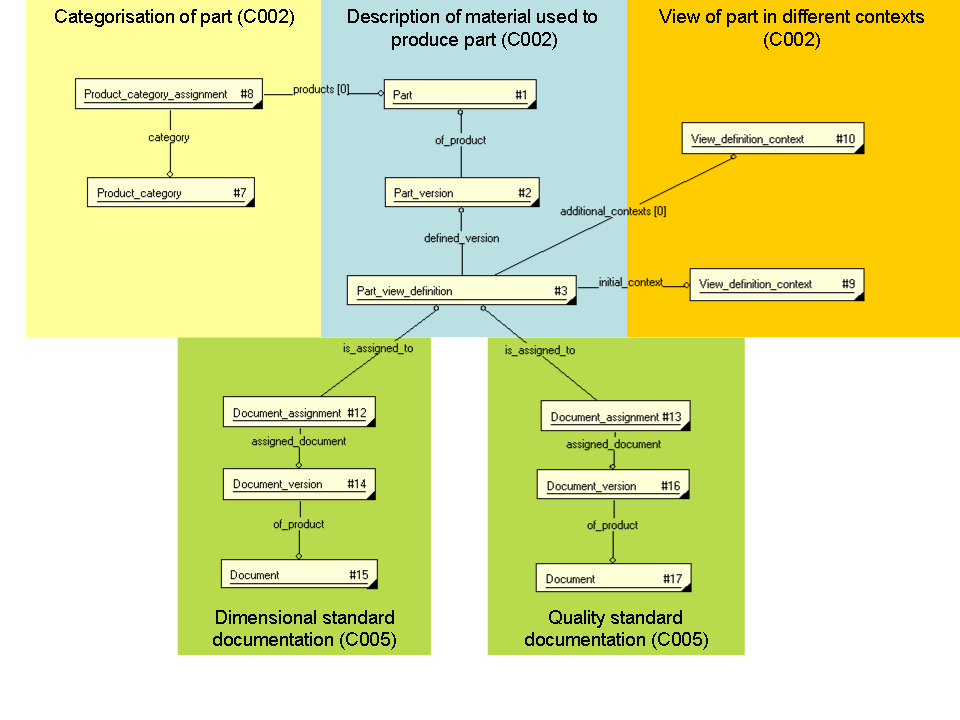

The figure below illustrates how material list items are characterized.

Characterize maintainable part

A maintainable part is an identified part belonging to the installation.

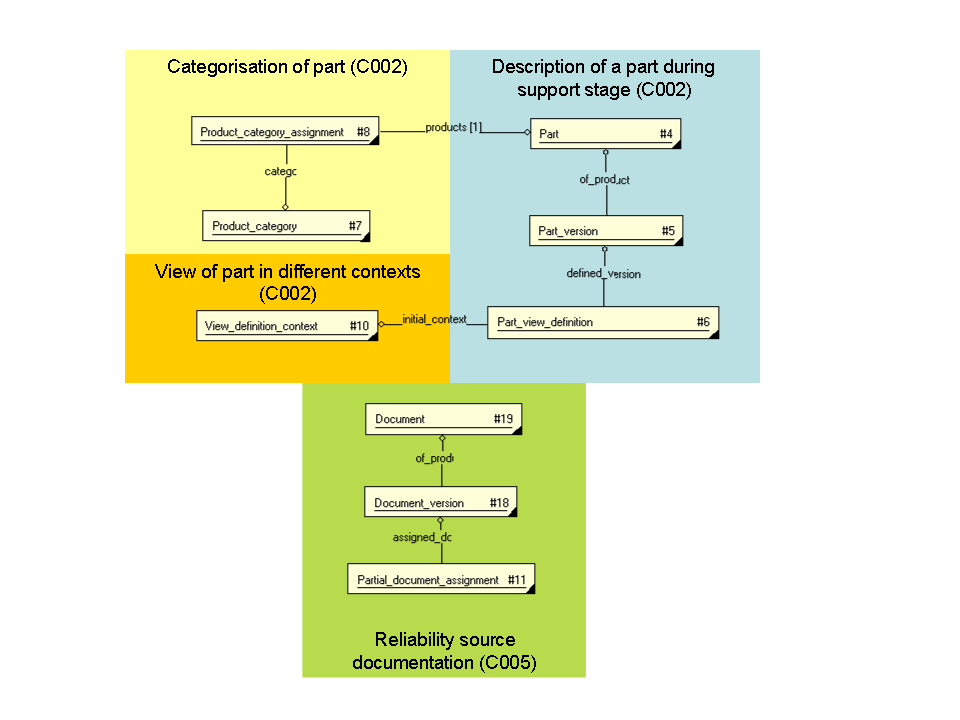

The figure below illustrates how maintainable parts are characterized.

| Business function id | Business function description | Business constraints | Characterize maintainable part | Characterize material list item | ||

| 1 | Assign manufacturer part number to the part | There shall be zero or one instance of the class for one instance of a Part. The superclass as well as siblings to the class are permitted to identify a part. There shall be one or more instances of an identifier for one instance of a Part. | x | - | ||

| 2 | Assign code type identifier to the organization that assigned the part identifier | x | - | |||

| 2.1 | # continue | There shall be zero or one instance of the class for an organization. Use class organization_identification_code when subtype is unknown. | x | - | ||

| 2.2 | # continue | There shall be one instance of the class if Step #2.1 has no instance, otherwise zero instance is permitted. | x | - | ||

| 3 | Assign code type identifier to the part version that is represented | There shall be one or more instances for an instance of Step #1. | x | x | ||

| 3.1 | Define the part to be maintainable | There shall be one or more instances for an instance of Step #3. | x | - | ||

| 4 | Assign description of part characteristics, e.g. a rotating part | NA | x | - | ||

| 4.1 | Classify the representation of the description | There shall be one instance of the class for an instance of Step #53. | - | - | ||

| 4.2 | Classify the representation context for the Main part characterization description | NA | - | - | ||

| 5 | Assign additional description of part characteristics, e.g. seal, material, specific and general item data | There shall be zero, one or more instances of the class for an instance of Step #3.1. | x | - | ||

| 6 | Identify part height | There shall be one instance for one instance of Step #1. There shall be one instance of Step #10 for one instance of 'exchange_data'. | x | - | ||

| 7 | Identify part width | There shall be one instance for one instance of Step #1. There shall be one instance of Step #10 for one instance of 'exchange_data'. | x | - | ||

| 8 | Identify part length | There shall be one instance for one instance of Step #1. There shall be one instance of Step #10 for one instance of 'exchange_data'. | x | - | ||

| 9 | Identify part weight | There shall be one instance for one instance of Step #1. There shall be one instance of Step #10.5 for one instance of 'exchange_data'. | x | - | ||

| 10 | Describe dimensional unit code applied | There shall be one instance for one instance of Step #11.1. | - | - | ||

| 10.1 | Classify representation of a measured value | There may be zero or one instance per instance of Step #11 and 11.1. | - | - | ||

| 10.2 | Classify context for numerical representation | There may be zero or one instance per instance of Step #11 and 11.1. | - | - | ||

| 10.3 | Classify representation of a calculated value | There may be zero or one instance per instance of Step #11 and 11.1. | - | - | ||

| 10.4 | Classify representation of a predicted value | There may be zero or one instance per instance of Step #11 and 11.1. | - | - | ||

| 10.5 | Describe weight unit code applied | There shall be one instance for one instance of Step #11. | - | - | ||

| 11 | Identify unit code for weight | There shall be one instance for one instance of Step #10.5. | - | - | ||

| 11..1 | Identify unit code for dimension | There shall be one instance for one instance of Step #10. | - | - | ||

| 12 | Identify hours as unit of measure for time based properties | There shall be one class instance for one entity type instance | - | - | ||

| 12.1 | Define unit of measure for a quantity | There shall be one class instance for one entity type instance | - | - | ||

| 12.2 | Identify unit for any value type | There shall be one class instance for one entity type instance | - | - | ||

| 13 | Assign a value for mean time to failure to a part | There shall be one or more instances for one instance of Step #1. If more than one instance applies, at least one of the referred values in Step #10.2, 10.4 or 13.3 shall be different. | x | - | ||

| 13.1 | NA | NA | - | - | ||

| 13.2 | NA | NA | - | - | ||

| 13.3 | Assign a document that describes the basis for a reliability value | There shall be one instance per instance of Step #13. | x | - | ||

| 13.4 | Identify document version number | NA | - | - | ||

| 13.5 | Identify the reliability algoritm document | One instance shall apply to one or more instances of Step #13.1. | - | - | ||

| 14 | Identify mean time to repair of part | There is one instance for each combination of one instance of Step #1 and one or more instances of Steps #10.1, 10.3 or 10.4. | - | - | ||

| 14.1 | Classify representation of a maintainability value | NA | - | - | ||

| 15 | Identify Material list item by its list item identifier | - | x | |||

| 16 | Assign description to a Part in a Material list | - | x | |||

| 16.1 | Identify a context for the Material list item | - | - | |||

| 16.2 | Categorize a part as a Material list item | - | x | |||

| 17 | Assign specific remarks to the Part in the parts list | - | x | |||

| 18 | Identify part surface finishing type or standard used (e.g. galvanized) | - | x | |||

| 19 | Identify Material list item size (e.g. 11x7, M8) as defined by the standard | - | x | |||

| 19.1 | Classify representation of Material list item size | - | - | |||

| 20 | Identify measures of the Material list item (nominal size in l*h*w) | - | x | |||

| 20.1 | Classify representation of Material list item measures in l*h*w | - | - | |||

| 20.2 | Classify representation context for Material list item dimensions | - | - | |||

| 21 | Identify standard used for the Material list item dimensions (e.g. DIN 6780) | - | - | |||

| 22 | Assign a document representing the dimensional standard | - | x | |||

| 23 | Identify Material list item mass | - | x | |||

| 24 | Identify unit of measure for Material list item mass | - | - | |||

| 25 | Assign a document representing the quality standard | NA | - | x | ||

| 26 | Identify quality standard used to build the part (e.g. DIN 267 FORM A) | There shall be one instance for one instance of Step #15. | - | - | ||

| 27 | Identify main contrator purchase type for Material list item | There shall be zero or one instance of 'exchange_data' for one instance of Step #15. | - | x | ||

| 27.1 | Identify a code value to represent the maintenance level | There shall be one instance for one instance of 27.2 | - | - | ||

| 27.2 | Identify that a string value is provided by the contractor | There shall be zero or one instance for one instance of 27. | - | - | ||

| 28 | Identify Material list item quantity to be purchased | There shall be one instance of 'exchange_data' for one instance of Step #15. | - | x | ||

| 29 | Identify unit of measure for purchase of Material list item | There shall be one instance of 'exchange_data' for one instance of Step #28. | - | - | ||

| 29.1 | Describe code for unit of measure | There shall be one instance for one instance of Step #29. | - | - | ||

| 30 | Identify Material list item quantity to be used for production | There shall be one instance of 'exchange_data' for one instance of Step #15. | - | x | ||

| 31 | Identify unit of measure for issue of the Material list item to production | There shall be one instance of 'exchange_data' for one instance of Step #30. | - | - | ||

| 32 | Identify the life cycle stage for which the data are valid | - | - | |||

| 32.1 | Classify 'Support_stage' as a life cycle stage | x | x | |||

| 32.2 | Classify 'Production_stage' as a life cycle stage | - | x | |||

| 33 | Identify the application domain for which the data are valid | - | - | |||

| 33.1 | Classify 'Product_life_cycle_support' as an application domain | x | x | |||

| 33.2 | Classify 'Manufacturing_processes' as an application domain | - | x | |||

| 34 | Assign an identifier to the support view of the maintainable part at its intended usage | There shall be no more than one instance of the identifier for one Part_view_definition instance. | - | - | ||

| 35 | Assign the Allowance Parts List identifier that applies to the support view of the maintainable configuration item at its intended usage | There shall be no more than one instance of the identifier for one Part_view_definition instance. | x | - |

Table 0 — Business functions and rules

Rules applied for material list items

Rules applied for maintainable parts

© OASIS 2010 — All rights reserved