| Business DEX (NDLO002):— Maintenance_task_identification | Date: 2007/10/12 12:27:18 Revision: 1.32 |

Task identification and versioning

A maintenance task is identified by a Task method dentification code. The encoding system should be defined and documented. A task always has one or more versions. A version is identified by a Task_method_version_identification_code.

Task structure (task_sequence, category, type)

A sequence of tasks can be defined by using two identifiers related to a task:

A task can be categorized using Task_category_characterization. A task category could be e.g. planned, corrective etc. It is also possible to define the type of task, e.g. Mandatory Maintenance, Repair Task, Availability Routine Item. The business object does not specify or standardize the valid entries. This is up to the project to define.

Product/Part identification

The following information is required to identify a part as a maintainable part (product in focus) to which the task is being assigned:

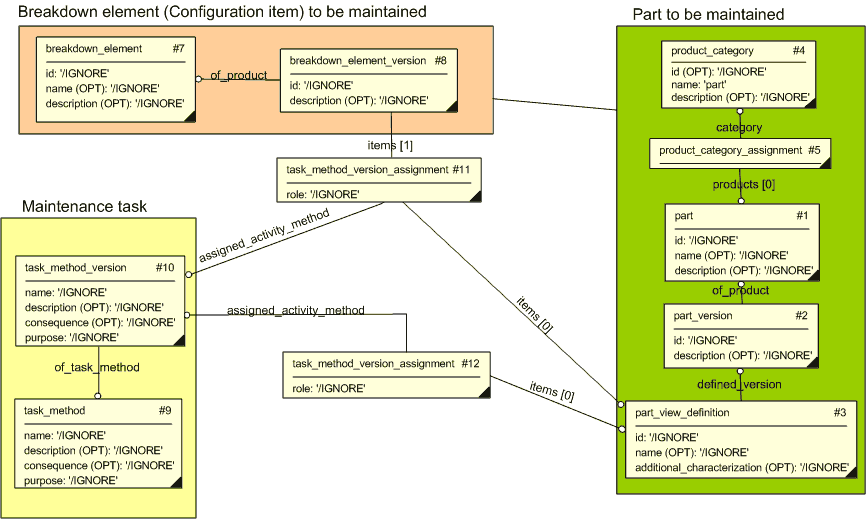

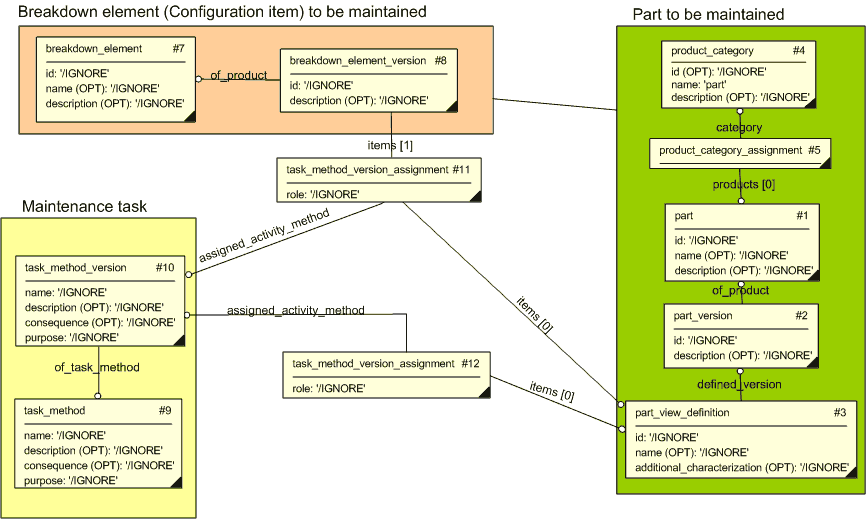

Breakdown element identification

The following information is required to identify a breakdown element as a configuration item (product in focus) to which the task is being assigned:

Task applicability (effectivity)

The business object applies a version of a task to a particular configuration item and maintainable part using a task_method_version_assignment relating the reference data maintenance_task_applicability. View_definition_context defines in which context a particular part view definition is applicable. The business object also allows the assignment of task versions to part view definitions independent of the breakdown element assignment. Then the reference data task_for_part is used. Attributes like

are assigned. This means that these attributes are independent of the breakdown structure.

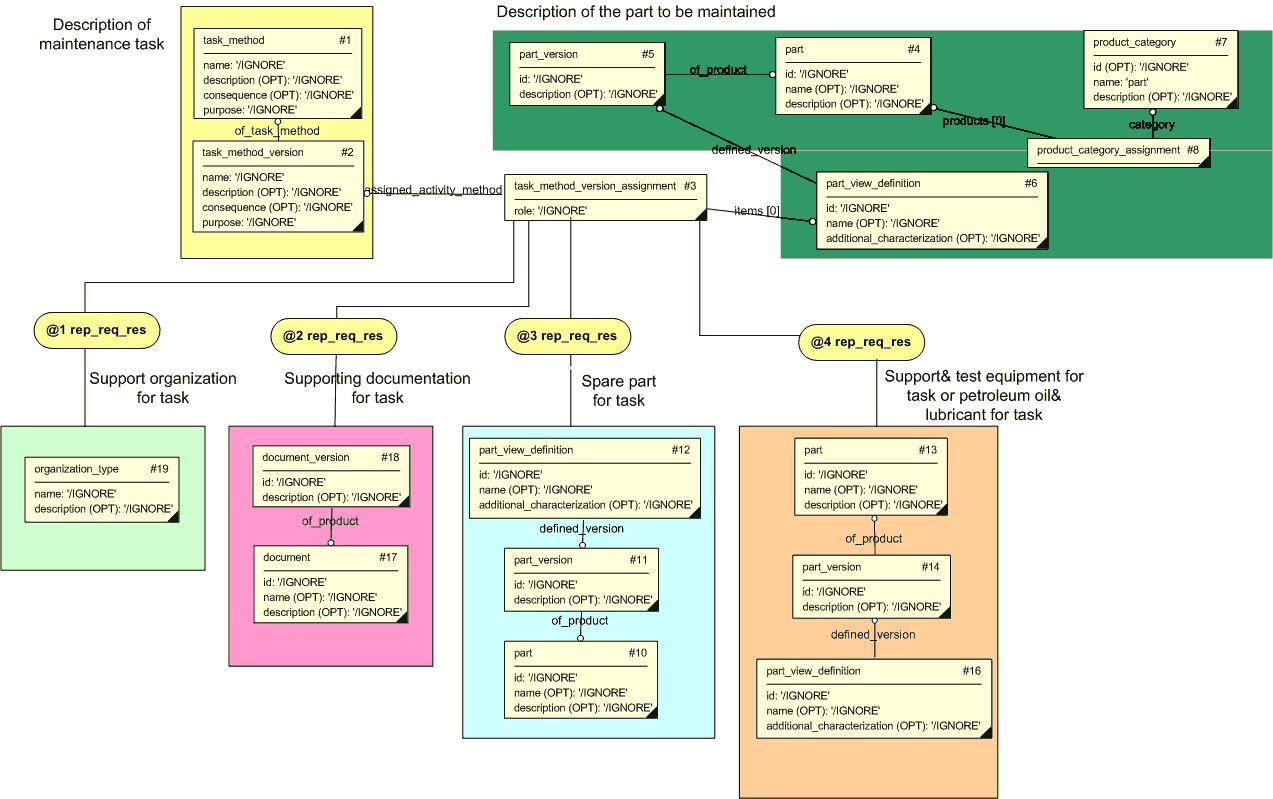

Maintenance task resources

Maintenance task resource identifies resources required to execute the task. Required resources can include:

Purpose

This NDLO-DEX shall exchange maintenance task data for maintenance planning and deployment, and for the maintainer. It shall exchange maintenance task data from the product development stage through the retirement stage, as input to management processes, technical analyses and support.

Usage

This NDLO-DEX provides input data for risk and maintenance task analysis processes, for development of maintenance plans and the support solution including support resource planning and scheduling for the product in focus. It applies to data exchange between maintenance task developers as well as between developer and end user. Moreover it identifies maintenance task data requirements for a product acquisition and for maintenance contracts.

This section provides an overview of the business objects. The diagrams in this section are included to give a high level introduction to the concept. They are not complete but give an overview of how the detailed diagrams (also found on this page) are structured.

Maintenance task identification and usage

The figure below describes maintenance tasks. The yellow rectangle to the right contains entities describing the maintenance task itself, by providing information such as task frequency, duration, training needed, etc.

Maintenance task resource

The figure below is a high level introduction to the maintenance task identification and usage business object where only main entities of the model are included. Details are included in the more detailed diagram also included on this page. The dark green box represents the parts to be maintained The maintenance task model is included in the yellow box. The various required resources for performing the maintenance task (red, pink, blue and light green boxes) are connected to the The boxes at the bottom of the diagram represents requirements or necessities in order to perform the task:

This NDLO-DEX is divided into two business objects (BO), each supporting various business functions. The table below indicates which functions are available in the different business objects. A "x" in the table means that the function is available for the business object. The column "BO 1" represents the business object maintenance task identification and usage, the column "BO 2" the maintenance task resource.

|

Business function id (BF #) |

Business function description |

Business constraints |

BO 1 |

BO 2 |

|

|---|---|---|---|---|---|

| 1 | Identify the part that the task applies to, at its intended usage | An instance shall have one instance of BF #1.3 and one or more instances of each of BF #3. There may be zero instances in an exchange file. | x | x | |

| 1.1 | Categorize the part subject to task performance as a maintenance object | There shall be one or more instances of the class for one instance of BF #1. There shall be one instance for one instance of BFs #1.2 and 1.3. | x | - | |

| 1.2 | Assign version identifier to the maintenance object | There shall be one unique identifier for one instance. There may be one or more entity instances for one instance of BF #1.3. | x | x | |

| 1.3 | Identify the maintenance object by its manufacturer part number | There shall be one or more instances for one instance of BF #1 or BF #4. There shall be at least one identifier instance for a part. There shall be zero or one instance of this identifier class for a Part. Other class names such as the superclass and siblings to the class are permitted to identify a part. | x | x | |

| 1.4 | Identify the breakdown item to which the task applies | NA | x | - | |

| 1.5 | Relate the breakdown element to its parent part | There shall be one instances for each pair of BF #1.1 and BF #1.4. | x | - | |

| 1.7 | Assign version identifier to the breakdown element | An instance shall have one more instances of BF #1.5. | x | - | |

| 2 | Assign CAGE code to the organization that assigned the part identifier | There shall be one instance for one identifier instance. | - | - | |

| 2.1 | Assign CAGE code to the organization that assigned the part identifier | There shall one and only one instance for one identifier instance. Other External_class.names, both of type Identification_code and Name, are permitted. | - | - | |

| 3 | Relate the task to the part (maintenance object) and breakdown element it applies to | There shall be one instance for each combination of BFs #3.1, #1 and #1.5. There shall be one instance of BF #1 or BF #1.5 for an instance of BF #3.1. An instance shall relate to zero or one instance of BF #98. | x | - | |

| 3.1 | Identify version of the task method | There is one instance for one or more instances of BF #3. There shall be one or more instances for one instance of BF #4. | x | x | |

| 4 | Assign an code type identifier to a task_method | An instance of the class is unique in the context of BF #1.6. There shall be one instance for one instance of the entity. There shall be one or more instances in an exchange file. | x | x | |

| 4.1 | Classify task_method as maintenance task | All Task_method with Task_method_identification_code shall be classified with Maintenance_task | x | x | |

| 5 | Identify task name | Use of name is optional and applies only if BF #4 has data. One instance shall relate to one or more instances of BF #1.. | - | - | |

| 6 | Identify each maintenance evolution sequencer in task code | An instance is unique in the context of BF #6.1. There shall be one or more instances for one instance of BF #6.1. | x | - | |

| 6.1 | Describe the maintenance evolution sequencer | x | - | ||

| 6.2 | Relate the task to the product functional breakdown element it applies to | There shall be zero or one instance for an instance of BF #4 and BF #3.1. | x | - | |

| 7 | Identify task sequence inside a maintenance evolution | One or more instances may apply to one instance of BF #6. Any instance may apply to any instance of BF #6. | x | - | |

| 7.1 | Describe the maintenance task sequence | x | |||

| 8 | Relate the task code to the encoding system document that defines the code | One instance of the class applies to each anstance of BF #4. | x | - | |

| 9 | Identify document number | There shall only be one instance for one instance of BF #9. | - | - | |

| 10 | Provide additional information about a task for usage on a specific part/location | There shall be one or two instances of <exchange_data> for one instance of BF #4. | x | - | |

| 10.1 | Classify the representation of the maintenance task additional information | NA | - | - | |

| 10.2 | Classify the representation_context of the maintenance task additional information | NA | - | - | |

| 11 | Describe the task briefly | There shall be one instance for one instance of BF #4. | x | - | |

| 12 | Define the objective of the task | There shall be one or two instances of <exchange_data> for one instance of BF #4, but not more than one per type 1 and 2. | x | - | |

| 13 | Provide recommended maintenence level for task usage | There shall be one instance of <exchange_data> for one instance of BF #100. | x | - | |

| 13.1 | Describe the maintenance level | x | - | ||

| 14 | Provide lowest maintenence level capable of task usage | There shall be one instance of <exchange_data> for one instance of BF #100.1. | x | - | |

| 14.1 | Describe the maintenance level | x | - | ||

| 15 | State if task method is condition based or not | There shall be zero or one instance of <exchange_data> for one instance of Task_method_version_assignment classified as Task_for_part | x | - | |

| 17.3 | Characterize the maintenance concept of the task | There shall be one instance of <exchange_data> for one instance of BF #4. | x | - | |

| 18.1 | Identify maintenance concept of the task through a code | There shall be zero or one instance of <exchange_data> for one instance of BF #18.2. | - | - | |

| 18.2 | Identify maintenance concept of the task through a name | There shall be zero or one instance of <exchange_data> for one instance of BF #18. | - | - | |

| 18.3 | Assign a Encoding system document to the name of the assigned property | - | - | ||

| 18.4 | Identify the document version number | - | - | ||

| 18.5 | Identify the document that describes the encoding system | NA | - | - | |

| 18.6 | Identify document number | NA | - | - | |

| 19 | Characterize maintenance task type | There shall be one instance of <exchange_data> for one instance of BF #4. There shall be one or more instances for one instance of BF #6.1. | x | - | |

| 19.1 | Identify maintenance task type code | There shall be zero or one instance of <exchange_data> for one instance of BF #19.2. | - | - | |

| 19.2 | Identify maintenance task type name | There shall be zero or one instance of <exchange_data> for one instance of BF #19. | - | - | |

| 21 | Define task frequency, i.e. mean number of days between task performance on this maintenance object | There shall be one instance of <exchange_data> for one instance of BF #4. | x | - | |

| 21.1 | Identify unit of measure for task frequency | NA | - | - | |

| 21.2 | Identify how the task frequency value was derived | NA | - | - | |

| 21.3 | Classify the context for the numerical representation | NA | - | - | |

| 21.4 | Identify the value for any type of periodicity | There shall be one or more instances per instance of BF #20. | - | - | |

| 21.5 | Identify unit for any value type | There shall be one class instance for one entity type instance | - | - | |

| 22 | "Define total estimated duration (calendar time) for a task " | There shall be one instance of <exchange_data> for one instance of BF #4. | x | - | |

| 22.1 | Identify unit of measure for task duration | NA | - | - | |

| 22.2 | Identify how the task duration value was derived | NA | - | - | |

| 23 | Define if special training is needed to perform task | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 24 | Provide special requirements for support to perform maintenance task (e.g. manufacturer support) | There may zero, one or two instances of <exchange_data> for one instance of BF #4, but not more than one per type 1 and 2. | x | - | |

| 25 | Define if item shall be removed from functional location for use of task | There shall be one instance of the Class classified as Removal_route_requirement for an instance of Assigned_property classified as Part_removal | x | - | |

| 26 | Assign description of a removal route to the functional location of a maintainable part | There shall be zero or one instance for one instance of BF #1.4 There shall be one instance for one instance of BF #25. | x | - | |

| 26.1 | Identify one or the existence of multiple removal routes | If there are more then one Removal_route (value is 'Yes') then removal routes are found in Additional_removal_route_identifiers. | x | - | |

| 26.2 | Identifiy multiple removal routes | There shall be zero or one instance of Additional_removal_route_identifiers for one instance of Part_removal_route | x | - | |

| 26.3 | Relate the removal route code to the encoding system document that defines the code | There shall be one or more instance for one instance of Identification_assignment classified as Part_removal_route | x | - | |

| 26.4 | Identify the document that describes the removal route codes | There shall be one instance for one instance of BF #26.2. | x | - | |

| 27 | State if specific infrastructure requirements apply to perform the maintenance task | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 28 | Relate the task to the resource items needed for task performance | There are one or more instances per instance of BF #3. | - | x | |

| 28.1 | Identify organization types as resource items | NA | - | x | |

| 28.2 | Identify documents as resource items | NA | - | x | |

| 28.3 | Identify repair parts as resource items | An insatance may have one or more instances of BF #45. | - | x | |

| 28.4 | Identify devices, tools and supplies of resource items | There can be one or more instances of Part_view_definition with SPMIG_code for one instance of #28.4 | - | x | |

| 28.41 | Identify special support and test equipments of resource items | - | x | ||

| 28.43 | Identify Petroleum, oil and lubricants of resource items | - | x | ||

| 28.5 | Identify infrastructure elements of resource items | NA | - | - | |

| 28.6 | Identify buildings or facilities as resource items | NA | - | - | |

| 28.7 | Identify human beings (e.g. worker) as resource | NA | - | - | |

| 28.8 | Relate resource item to task | NA | - | x | |

| 29 | Define the required type of work centre needed to perform a task | There shall be one instance for one instance of BF #3. | - | x | |

| 29.1 | Identify the required type of work centre needed to perform a task | There shall be one instance for one instance of BF #3. | - | x | |

| 29.2 | Identify the code for the required type of work centre needed to perform a task | There shall be one instance for one instance of BF #3. | - | x | |

| 30 | Define role/categrory of required work centre type | There shall be one instance for one instance of Task_method_version_assignment | - | x | |

| 31 | Assign to a type of organization the level of maintenance it shall be capable of | There shall be one instance for one instance of BF #3. | - | x | |

| 32 | Define minimum skill level of a resource required to perform a task | There shall be one instance for one instance of BF #3. | - | x | |

| 32.1 | Define the name of the minimum skill level of a resource required to perform a task | NA | - | - | |

| 32.2 | The code identifying the minimum skill level of a resource required to perform a task | NA | - | - | |

| 33 | Define needed sum of man-hours at given skill level and workshop type to perform a task | There shall be one instance for one instance of BF #3. | - | x | |

| 34 | Define needed quantity of persons at the given skill level and workshop type to perform a task | There shall be one instance for one instance of BF #3. | - | x | |

| 34.1 | Define unit of measure for a quantity | NA | - | - | |

| 34.2 | Identify count unit for resource item replacement | There shall be one instance of <exchange_data> for an instance of BF #28.3. | x | ||

| 34.3 | Provide description/name of count unit for resource item replacement | The entity instance is the same as in BF #34.2. There shall be one instance of <exchange_data> for one instance of BF #34.2. | - | x | |

| 35 | Define needed calendar hours for a given skill level and workshop type to perform a task | There shall be one instance for one instance of BF #3. | - | x | |

| 36 | Provide identification of documents required to perfom or support a task | There shall be one instance for one instance of BF #3. | - | x | |

| 36.2 | Identify types of documents required to perform task | There shall be one instance for one instance of BF #3. | - | x | |

| 36.3 | Identify version of the document | There shall be one instance for one instance of BF #36.1. | - | x | |

| 37 | Assign support material identifier code to the part | - | x | ||

| 38 | Mapping instruction for special and common support and test equipment and POL products | - | x | ||

| 38.1 | Classify Part as Petroleum, oil and lubricant | x | |||

| 38.2 | Classify Part as Special support and test equipment | x | |||

| 38.3 | Classify Part as Common support and test equipment | x | |||

| 43 | Assign part number to support material items | There shall be zero, one or more instances for one instance of BF #37, and zero or one instance for one set instance of BFs #37 and 50. | - | x | |

| 44 | Assign manufacturer part number to the spare part | There may be zero, one or more instances for one <exchange_data> instance of BF #4. There shall be one or more instance for one instance of BF #44.1. | - | x | |

| 44.1 | Assign NATO Stock Number (NSN) to resource item as spare part | There shall be one or more instances for one instance of BF #44 even if <exchange_data> is unset. | - | x | |

| 44.2 | Identify part version for a type of spare part | There shall be one unique identifier for one instance. There may be one or more entity instances for one instance of BF #44. | - | x | |

| 44.3 | Identify part view for a part in the role of a spare part | There shall be one instance for one instance of BF #44.2. | - | x | |

| 45.1 | Provide a descriptive text to indicate if the required spares quantity is known | There shall be one instance of the class if BF #45.2 has a value. | x | ||

| 45.2 | Code to indicate if the required spares quantity is known | There shall be one instance of the class if BF #28.8 has no value. | |||

| 46 | Identify if part replacement (spare part usage) is conditional or mandatory during task performance | There shall be one instance for a combination of Part with OEM_part_type_code and Task_method with Maintenance_task_code | - | x | |

| 47 | Classify 'Product_life_cycle_support' as an application domain | Use of other class names is permitted. | x | x | |

| 48 | Classify 'Support_stage' as a life cycle stage | Use of other class names is permitted. | x | x | |

| 49 | Identify part version of support material items | There shall be one unique identifier for one instance. There may be one or more entity instances for one instance of BF #43. | - | x | |

| 51 | NA | - | - | ||

| 52 | Relate the task to the part (maintenance object) it applies to | There shall be one instance for each combination of instances of BFs #1, 4 and 53. | x | - | |

| 53 | Identify the parent part to which a set of maintenance tasks apply | There shall be one or more instances for one instance of BF #52. | x | - | |

| 54 | Identify the version of the parent part to which a set of maintenance tasks apply | There shall be one or more instances for one instance of BF #53. | - | - | |

| 55 | Define the maintenance task properties | NA | |||

| 56 | Identify the Part view definition | NA | |||

| 57 | Indicate if a manufacturing representative is required to perform a task | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 58 | Indicate if special material is required to perform a task | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 59 | List applicable technical manuals related to the system/equipment | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 60 | Identify the need for special tools to accomplish a task | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 61 | List special reporting requirements and other information pertinent to the Class that is not included elsewhere | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 62 | Indicate regulations, instructions, rules, etc which generate the task | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 63 | Define the number of systems/equipment installed on a top part (ship) | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 63.1 | Identify how the value is represented | NA | x | - | |

| 63.2 | Classify the context for the representation | NA | x | - | |

| 64 | Define the periodicity for task performance as required by the maintenance plan | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 64.1 | Identify unit for measurement of periodicity of task performance | There shall be one instance for one instance of Assigned_property classified as Maintenance_task_periodicity and String_representation_item.string_value is populated with a number | x | - | |

| 65 | Relate an installed Maintainable part to the system in which it is used | x | - | ||

| 66 | Identify the Maintenance requirement card number for first level tasks | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 66.1 | Identify the document version number | NA | x | - | |

| 66.2 | Identify the document number | NA | x | - | |

| 67 | Define the recommended number of systems/equipment that should be changed for the same task | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 67.1 | Identify how the task performance property was derived | NA | x | - | |

| 68 | Define the criticality code for the mission | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 68.1 | Identify the mission criticality | x | - | ||

| 68.2 | Identify the mission criticality code | x | - | ||

| 69 | Define the priority of the maintenance task in accordance with the task mission criticality code | There shall be zero or one instance of the class for an instance of Task_method_version_assignment classified as Task_for_part. | x | - | |

| 69.1 | Identify the priority number | x | - | ||

| 70 | The changes to the maintenance plan since last revision | - | - | ||

| 72 | Describe the semantics used to represent the change to the maintenance plan | - | - | ||

| 73 | Assign the maintenance plan table to the maintenance plan | - | - | ||

| 73.1 | Assign version identifier to the maintenance plan | - | - | ||

| 73.2 | Identifiy the maintenance plan document | - | - | ||

| 74 | Quantify the probability that the spare part shall be used when a task is performed on a maintainable part | There shall be zero or one instance of Assigned_property classified as Spare_part_usage_probability for an instance of Required_resource_by_resource_item classified as Part_as_resource. | - | x | |

| 74.1 | Classify the representation of the quantity value as required value | There will be no more than one class instance for one instance of the value_component. | - | x | |

| 74.2 | Classify the representation context of the quantity value owner data | There will be no more than one class instance for one instance of the value_component. | - | x | |

| 74.3 | Provide unit of measure for probability of spare part usage | There shall be one instance for an instance of BF #74. | - | x | |

| 74.4 | Provide unit description for probability of spare part usage | The entity instance is the same as in BF #74.3. There shall be one instance of <exchange_data> for one instance of BF #74.3. | - | x | |

| 75 | Identify price of spare part | There shall be zero or one instance for an instance of Part_view_definition classified as Spare_part. | - | x | |

| 75.1 | Identify currency code for spare part price | There shall be one instance for an instance of BF #75. | - | x | |

| 75.2 | Provide description for monetary code | There shall be one instance for an instance of BF #75.2. | - | x | |

| 76 | Assign support material identifier code to the part | There shall be zero or one instance for an instance of Part_view_definition classified as Spare_part. | - | x | |

| 76.1 | Describe the part with SPMIG_code | - | x | ||

| 77 | Relate the SPMIG code to the encoding system document that defines the code | One instance of the class applies to each anstance of BF #76. | - | x | |

| 77.1 | Identify document number | There shall only be one instance for one instance of BF #77. | - | x | |

| 78 | Assign a document applicable to the spare part as a resource item | There shall be zero or one instance of Document_assignment classified as Part_for_task_on_drawing for a Part_view_definition classified as Spare_part | - | x | |

| 78.1 | Identify the document | There shall be zero or one instance for one instance of BF #78. | - | x | |

| 79 | Identify part position number on drawing | There shall be zero or one instance for an instance of Part_view_definition classified as Spare_part. | - | x | |

| 80 | Identify the sequential number of item in the maintenance plan | There shall be one or more for one instance of Part with OEM_part_type_code | - | x | |

| 81 | Assign the maintenance plan table to the maintenance plan | - | x | ||

| 82 | The changes to the maintenance plan since last revision | - | x | ||

| 83 | Assign NATO Stock Number (NSN) to resource item as support equipment | There shall be one or more instances for one instance of BF #43 even if <exchange_data> is unset. | - | x | |

| 84 | Relate descriptive information to support equipment | NA | - | x | |

| 84.1 | Describe a support equipment | There shall be one instance for an instance of BF #84. | - | x | |

| 85 | Identify if support equipment is repairable | There shall be one instance for an instance of BF #5. | - | x | |

| 85.1 | Code identifying the support equipment repairability | There shall be one instance for an instance of BF #43.2. | - | x | |

| 85.2 | Name identifying the support equipment repairability | There shall be one instance for an instance of BF #43. | - | x | |

| 86 | Quantify the probability that the support equipment shall be used when a task is performed on a maintainable part | There shall be zero or one instance of Assigned_property classified as Support_equipment_usage_probability for an instance of Required_resource_by_resource_item classified as Device_tool_supply_item. | - | x | |

| 87 | Identify the sequential number of item in the maintenance plan | There shall be one or more for one instance of Part_view_definition with SPMIG_code | - | x | |

| 88 | Assign a document applicable to the support equipment as a resource item | There shall be zero or one instance of Document_assignment classified as Part_for_task_on_drawing for a Part_view_definition classified as Spare_part | - | x | |

| 88.1 | Identify the document | There shall be zero or one instance for one instance of BF #78. | - | x | |

| 89 | Identify part position number on drawing | There shall be zero or one instance for an instance of Part_view_definition classified as Spare_part. | - | x | |

| 91 | Identify price of support equipment | There shall be zero or one instance for an instance of Part_view_definition classified as Support_equipment. | - | x | |

| 92 | Define unit of measure for a quantity | NA | - | x | |

| 92.1 | Identify count unit for resource item required | There shall be one instance of <exchange_data> for an instance of BF #28.4. | - | x | |

| 92.2 | Provide description/name of count unit for resource item required | The entity instance is the same as in BF #92.1. There shall be one instance of <exchange_data> for one instance of BF #92.1. | - | x | |

| 94 | Identify if support equipment usage is conditional or mandatory during task performance | There shall be one instance for a combination of Part with OEM_part_type_code and Task_method with Maintenance_task_code | - | x | |

| 95 | The changes to the maintenance plan since last revision | - | - | ||

| 96 | Assign the maintenance plan table to the maintenance plan | - | - | ||

| 97 | Identify the work centre responsible for maintenance of the configuration item | x | - | ||

| 98 | Identify the name of the work centre | There shall be one instance for one instance of Product_based_location_identification classified as Work_centre_for_configuration_item | x | - | |

| 98.1 | Identify the the work centre with a code | x | - | ||

| 99 | Assign the maintenance plan table to the maintenance plan | x | - | ||

| 100 | The changes to the maintenance plan since last revision | x | - | ||

| 101 | Relate the maintenance task to the level of maintenance | x | - | ||

| 101.1 | Relate the maintenance task to the lowest level of maintenance | x | - |

Table 0 — Business function and constraints

Cardinality

Uniqueness

© OASIS 2010 — All rights reserved